|

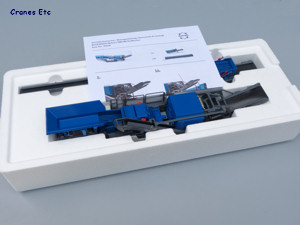

| Kleemann box.

|

|

|

| The crusher

assembled. |

|

| Good structure.

|

|

| Hopper and pre

screen. |

|

| Optional side

conveyor. |

|

| Side conveyor

folded out. |

|

| Good detailing. |

|

| Conveyor top. |

|

| Ladder folds

down and tilts out. |

|

| The side

conveyor can be set to return material to the crusher. |

|

| Being loaded

with a Link Belt excavator. |

|

| Impressive load

for a truck. |

|

Kleemann GmbH is part of the

Wirtgen Group and it

manufactures crushers and screening plant. It has

a long history, being founded in 1857.

The MOBIREX MR 110 EVO is a mobile impact crusher suitable for

processing blasted natural stone, asphalt and demolition

waste. It can process up to 350 tonnes of material per hour. The machine is readily

transportable and has a weight of about 54 tonnes

including the screening unit, and 44 tonnes without it.

Packaging

The model comes in a Kleeman branded box which has a

high quality photo and very good technical information

about the real machine in both English and German.

There were no defects or missing parts on the review

model.

There are three elements to the model and a good colour

instruction sheet describes the assembly into a site

configuration, although not all the features of the

model are described.

Detail

This is a heavy model and the undercarriage has detail

with the plastic tracks looking good, and the metal

track frames are simple, without working rollers.

The feeding unit has fixed hopper sides and is mounted

on a good structure which has the mounting springs

detailed. The Pre screen is plastic and the feed

to the side conveyor can be seen underneath. The

entrance to the crusher has rubber strips attached to

the cover to prevent

fly-out from the crusher. Safety equipment is

marked with red plastic elements.

The body sides have very sharp Kleemann graphics with

various panel details contained within the casting.

Plastic ladders lead up to the work platform. The

floors have diamond plated non-slip surfacing and the

handrails are metal.

The main engine enclosure is a large metal casting with

grille details.

The discharge conveyor belt is rubber and there is a detailed

drive motor at the end. A magnetic separator is

modelled in plastic.

A side conveyor is modelled

and it has a metal structure and rubber belt. It

takes oversize material from the optional screening

unit for side discharge or return to the

crusher. Another optional conveyor can be fitted

under the main screen and it also has a rubber belt.

The optional screen unit has a plastic screen with an

excellent colour match to the metal hopper, and the belt

is rubber. Drive motors and transport legs are

modelled in plastic.

Features

The plastic tracks roll well on a rough surface.

The two access ladders have fold down sections and the

larger one also tilts out to provide an inclined angle.

An optional side conveyor can be fitted on either side

under the main screen. It has a working belt.

The crusher cover tilts up.

The fixed side conveyor opens up and can be positioned

anywhere along a wide arc. It has a working belt.

The magnetic separator can be lowered to be above the

main discharge conveyor. It is also removable so

the model can be displayed without it.

The optional screen has a working belt and it can be

fitted to the crusher or displayed separately on

fold-down legs. The screening box is also

removable from the belt structure.

Quality

This is a very solid and robust model with a high metal

content. Plastic elements have a very good colour

match to the metal parts.

The paint finish is high quality and is matched with

sharp graphics.

Price

The model is relatively pricey probably reflecting the

high metal content and likely lower production numbers.

Overall

It is good to see another quarrying model and Conrad has

not disappointed with this Kleemann machine. It is

a very strong model with plenty of functionality.

Hydraulic hoses and cables would have added some more

detail, but nonetheless it is highly recommended.

Footnotes

The model first appeared at the Intermat Exhibition in

April 2012.

|

|

|

|

|

| The parts in

the box. |

|

|

Profile view. |

|

| Optional

screening unit fitted.

|

|

| Plastic tracks

look fine. |

|

| View

underneath. |

|

| Conveyors out. |

|

| Ladder up to

the work platform. |

|

| Magnetic

separation unit folds down. |

|

| Magnetic

separator is removable. |

|

| Screening unit

has transport legs. |

|

| Loaded on a

Faymonville trailer. |

|

| Great display

pose. |

|