|

|

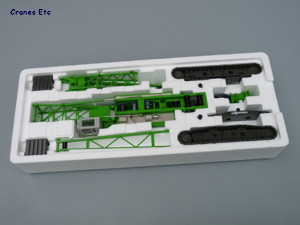

Sennebogen'Go for Green' branded

box. |

|

|

|

Rigged with a boom only. |

|

| Tilting cab is

plastic. |

|

| Plastic tracks

look pretty good.

|

|

| Textured

surfaces on top of the body. |

|

| Luffing jib

connection. |

|

| Top of the

luffing jib. The hook looks smart. |

|

| Maximum luffing

jib configuration.

|

|

| Maximum

non-luffing jib configuration. |

|

| The 5500 makes

excellent transport loads.

Nooteboom trailers do the honours. |

|

| 'Did you bring

the instruction manual?' |

|

| Body loaded on

a Nooteboom Euro Low Loader. |

|

| Standing on the

jacks. |

|

| Tracks fitted

and ready for the counterweight. |

|

The model of the Sennebogen 5500 was

the first mass-produced large crawler crane model and it

appeared as a prototype at the BAUMA exhibition in 2001,

and went on sale in 2002.

This version is in Sennebogen's 'Go for Green' livery and

is updated with some revisions to the original

model.

Packaging

The box sleeve reflects the Green Line branding and

contains two

polystyrene trays which have a large number of

individual pieces securely packed.

The review model was undamaged although there were two

manufacturing defects affecting the luffing jib

retaining ropes and the counterweight tray fixing.

Both issues were quickly resolved by Conrad.

An instruction sheet is provided, complete with

pictures, and it is in German and English. Although

helpful, it does not describe all aspects of the

assembly including the reeving of the luffing jib and

which winch drums to use. The winch drums should be

used as follows (numbering the winch drums 1 to 4 from front to back):

- 1

is used for the hook when there is only a main boom or

for the hook for the luffing jib if the crane is

using two hooks;

- 2 is used for the hook on the main boom when the

luffing jib is attached;

- 3 is a

double drum and controls the luffing of the main boom

using the pulleys on the A-frame (except the centre

pulley);

- 4 controls the luffing jib - the rope

goes under and around the single pulley on the body

and then up and over the centre pulley on the A-frame

and on up to the luffing gear pulleys.

Rigging the model takes some time and the instructions

are not as clear as they could be so a complete novice

might have some difficulty. In particular stringing up

the luffing gear requires patience and perseverance.

Detail

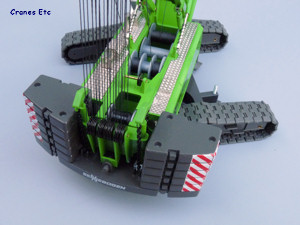

Each crawler track comes as a separate unit. The tracks

themselves are plastic made up of a large number of

interlocking sections. They look very good although

they are occasionally a little stiff so do not always

lie naturally. The only other moving parts on the track

frame are the main sprockets.

The main piece of the model crane consists of the cross

frame that links the two track frames, the crane body and first section

of boom. The cross frame snaps into position into

openings in the track frames and this provides a robust

fixing mechanism.

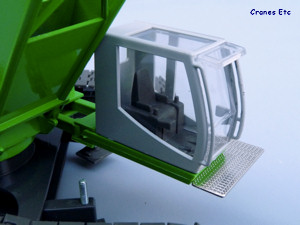

The cab is plastic

with grab rails and good interior details such as foot

pedals. The main body is relatively uncomplicated

except at the rear where the counterweight attachment

mechanism is modelled well, and is complete with cylinders and

lifting chains although the cylinder pistons would look

better if they were silver rather than green.

Four separate winches are available to be used: one for

luffing the main boom, one for the luffing jib and two

winch lines. The pulleys on the body and A-frame are

metal rather than the plastic of the first version of

the model and they are much better and roll freely.

The counterweight plate attaches with a pin and pairs of five weights

sit on top. Each counterweight

piece is cast with lifting lugs and is painted to

produce a very pleasing result. Not included on the

model are the ballast plates used on the real machine

which span between the track frames front and rear and

these would have added to the stability

of the model.

The first section of

the main boom is permanently fixed to the crane body

together with spring-loaded bars to prevent the boom

being over luffed into a vertical position. All sections of

the boom are made extremely well and look just great.

They join together using the plastic pin system which is

very effective.

The main boom head has

snap-in large plastic pulleys which are satisfactory but

perhaps not the best in their ability to free-roll, and they also appear to have an

over-large separation between the sheaves.

With the luffing jib attached an excellent cable

arrangement is provided to prevent the jib over-luffing and the thread type

hangs more naturally than on the original version of the

model.

The

pendant bars used to support the boom and jib are all modelled

in tough plastic and these are another revision from the

original model. They are pinned together so they

remain straight under tension and are a big improvement.

There is no dolly wheel at the end of the fly

jib and this would have been a worthwhile addition to

the updated model.

The hook is only

a single pulley affair but looks smart with chevron

stripes. It is metal and looks fine on

the fly jib but the main boom really calls for something

larger and again it would have been a nice improvement

on this update.

Features

The cab is mounted on a tilting and hinge arrangement so

that it can be moved inward to reduce the crane width

during transport and can be rotated upward to aid the

driver during lifts at height. As a minor detail it

would have been better if the walkway outside the cab

had been hinged so that it can be stowed during

transportation.

The four winches are operated by keys which are metal. They can also be

removed when not used so they do not distract from the

look although the holes remain.

The main strength of this model is the large variety of

ways the model can be displayed. It can be fully broken

down for transport so looks excellent on the appropriate

haulage vehicles. It can also be displayed in various

stages of assembly.

The crane can be rigged a number of ways. It can have

just a main boom of various lengths, including very

short if you want it. It can have a luffing

jib of different lengths giving an overall model height

of about 1.2m. Another option arises because the

reducer section at the top of the main boom can have jib

sections directly attached to create a long boom

with reducing section towards the top. Under this

configuration the model stands around 1.1m high.

In terms of stability the model is fine with the boom

and jib up but less so when they are at a big radius.

Quality

The casting of the boom

sections is very good and overall the model has a high

quality feel notwithstanding the production errors on

the review model.

The Sennebogen 'Go for Green' paint scheme looks really good

and the few graphics are sharp.

Price

Relatively speaking the model is now better value for money.

Overall

Although it is around 10 years since it first appeared,

this is still a great looking crane model and the small

improvements made to this version have been worthwhile.

It would have been nice if a few more changes had been

made such as metal tracks and ballast plates between the

track frames but no doubt this would have cost more.

It remains easy to recommend.

Footnotes

The Sennebogen 5500 crawler crane was originally made in

yellow and grey livery and was reviewed

here. The base model comes with the

full complement of ballast weights as per the real

crane. An extension kit was produced which

included an extra main boom

section and an extra jib section. It also had extra

ballast weights which add stability to the model but in

total are more than the real machine uses.

The model

was withdrawn from Conrad's online model list in

February 2006. In December 2006 a version in Mammoet

colours was introduced in a limited edition of 300

models. The extension set was also available in Mammoet

colours.

In 2011 this updated version was introduced, and it

was also made available in Franz Bracht colours as model

number 2733/03.

|

|

|

|

|

| Bottom tray. |

|

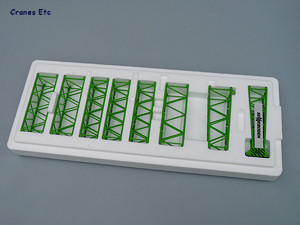

| Top tray.

|

|

| Counterweight

slabs are well formed. |

|

| Metal pulleys

are a big improvement on this version of the model. |

|

| Simple cab

interior. |

|

| Small hook for

a big boom. Only two pulleys are fitted on the

front of the boom head so they roll better. |

|

| Pendants are

much improved and are straight. |

|

| Using the

reducer section to produce a long boom. |

|

| Impressive boom.

|

|

| Body lifted up

so the low loader can drive away. |

|

| Self loading

one of the track assemblies. In reality it really

needs a winch line to lift the load. |

|

| Moving in to

self-lift the counterweight. |

|

| Ready for boom

up. |

|