| | Liebherr branded box. |  |  | | Instruction sheet. |  | | The casing is engaged so it can be driven in. |  | | The casing oscillator. |  | | The guide for the auger. |  | | Rigged for double rotary drilling where a CFA is within a casing which is also driven. |  | | The casing guide. Although not shown here there is a cutting ring which fits the bottom of the casing. |  | | The vibratory table. |  | | Rigged for driven piling with a hydraulic hammer. |  | | Pile guide. |

| The Liebherr LRB 255 is a versatile ground engineering machine which can be rigged to carry out a variety of techniques.

The base model was supplied rigged to drive sheet piles. This accessory set allows five more alternative configurations to be mounted on the LRB 255.

Packaging

The set comes in a standard Liebherr box style, and it is packed in two expanded polystyrene trays. Soft tissue surrounds some of the parts and gives a quality feel.

There is no information provided about the real machine of the accessory parts and techniques and a brochure or CD would have been a great addition to explain the various methods provided by the set. A simple instruction sheet is supplied and this adequately describes how to build the different configurations.

Detail

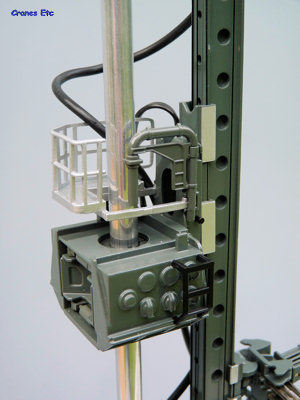

The kelly bar and auger configuration is all metal and fits to the sledge on the leader in the same way as all the other tools. It hooks onto pins at the top and is secured by a pin at the bottom. The kelly bar is not telescopic but has good detail within the casting. There are hydraulic lines running to the drive motors. The casing drive has a plastic adaptor which allows it to connect with the supplied metal casing. section. A casing oscillator attaches to the bottom of the leader and it is a well made part. Hydraulic cylinders allow the grip on the casing to be released and also to enable the top plate to rise and fall to push the casing up and down.

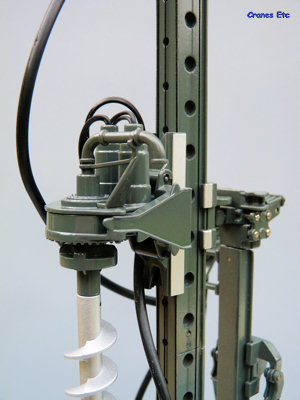

A second tool is a Continuous Fight Auger. It has a one piece metal drill string and the drive table is metal with hydraulic lines to the motors. The dill is steadied by a guide which clips to the bottom of the leader. It would have been nice if a piece of concrete supply pipe had been supplied to complete the arrangement.

The third variant is a double rotary drive which has a CFA mounted inside a driven casing. As the auger drives in the casing is also driven and both are extracted as concrete is pumped through the drill stem. Reinforcement is added after the machine finishes and this is a very efficient way of forming piles in sandy soils. The rotary drive and casing are all metal parts with similar details as other parts, and there is a plastic cutting shoe which can be fitted to the bottom of the casing.

A pile vibration drive comprises the fourth configuration. The vibratory table is detailed well and includes metal hand rails and ladders, and a pipe for filling piles with concrete. Again all parts are metal, and two lengths of thin pile are supplied which connect with an adaptor piece. The pile is positioned at the bottom using a guide.

A hydraulic hammer is the fifth tool available and it is a heavy part all in metal and includes tanks and hydraulic lines. It connects with one of the thin piles and a guide at the bottom of the leader holds the pile using a couple of plastic inserts.

Features

All five configurations can be mounted on the model easily and they are useable as pieces for transport pieces with perhaps the exception of the kelly bar arrangement which cannot have the auger disconnected from the kelly bar, and the kelly cannot be removed form the rotary drive.

The kelly bar can be rotated and slid through the rotary drive, and the casing oscillator attachment has opening jaws and the top clamp can be raised and lowered.

The drill strings on both CFA arrangements can be rotated.

The vibratory table has a rotating concrete delivery pipe.

The piling hammer can be raised and lowered within its casing.

Quality

These are high quality accessories which are almost entirely metal. The paintwork is very good and there are no graphics on the parts.

Price

The kit is relatively expensive reflecting the very high metal content and limited application of the parts.

Overall

These parts provide effectively five further different models to be configured on the base machine and illustrate a range of ground engineering techniques. They are very well made and are highly recommended.

Footnotes

The model first appeared at the Nuremberg Toy Fair in 2009.

|

| |

|  | | The lid stores the piles and casings. |  | | Set up to drill augured piles with a kelly bar. |  | | Motors and hydraulic cables on the rotary head. |  | | Rigged for continuous flight auger (CFA) piling. |  | | The drilling motor. |  | | The double rotary drill head. |  | | Rigged for vibratory drilling. |  | | Larger casing guide for the vibrated pile. |  | | Details of the hammer. |  | | A mini Liebherr diorama can be formed with the appropriate models. Here the LRB 255 is rigged with an auger and kelly bar. A LB 28 is on site together with an HS 855 handling crane and a Liebherr Truck Mixer fills a pile. |

|