| | Liebherr picture box. |  |  | | The lower tray. |  | | Overall detail level is very good. |  | | The tilting cab has the controls clearly modelled. |  | | Full counterweight stacked high. |  | | Very good roof detail. |  | | Boom sections are joined by tiny nuts and bolts. |  | | Tracks are removable. |  | | Configured as a dragline. |  | | Casting the bucket. |  | | It makes a very good low loader load. Here it is on a Goldhofer trailer. |  | | Unloading. |  | | The axles for the pulleys are retained with the yellow clips shown. |  | | Clip for the counterweight blocks. |

| There have been a few Liebherr crawler crane models manufactured over the years and the HS 855 HD is the first to be made by NZG.

The 855 is a duty cycle machine which means it can be used for a variety of applications where repetitive activities such as dragline or clam shell use can be stressful on certain machine parts so they are strengthened. It can also be configured as a crane, and used in foundation construction.

The machine typically weighs around 90t when in operation and the basic crane body forms a transport load of 59t with the crawlers attached. As a crane, it can lift up to 90t on the main boom and 25t on the auxiliary jib.

Packaging

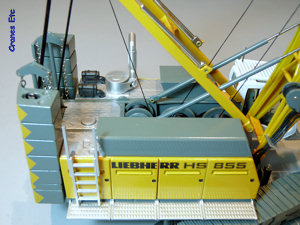

The box is in the typical Liebherr picture box style and the model and its various parts are packed into two expanded polystyrene trays. There were no defects or missing parts on the review model.

There is no information provided about the real crane which is a pity, but there are two instruction leaflets for assembling the model and they are in German and English. Although the leaflets are quite good they do not really do the model justice as it is highly engineered with a great many parts and so more detailed instructions with an inventory of parts would have been better. For additional information see the Assembly Guidance at the end of this review. Assembly of the crane takes a few hours as it has to be reeved and some of the parts are very small. So small in fact that particular care is advised to make sure that they are not dropped as they will be hard to find. NZG have helpfully included a bag of spare parts with the model which includes track links, a few screws and other parts.

Detail

The metal tracks are very nicely made and seem to be the same as provided on the LRB 255 model. They are mounted on removable track frames which include tiny rollers on the lower edge. Detail is very good with the Liebherr name cast into the main drive sprocket.

Between the tracks self-raising jacks are provided but the carbody counterweight is not, although it looks as though provision has made for it so perhaps it will appear as part of a later accessory kit.

The operator's cab is another part that appears to be shared with the LRB 255 model and this is fine as it is a high quality part. Internally, the cab has pedals and joysticks replicated. Externally the cab has lights, aerial, a mirror and windscreen wiper. The differences to the LRB 255 cab are that the debris guard is shorter and the grab rail is plastic rather than metal. The access platforms are slightly different and better quality, and they surround the body.

Detail on the crane body is very good, with grilles and handles contained within the panels. There is an access ladder to the roof which is plastic but it looks fine. The roof has a textured surface and there is a plastic exhaust system. The winches look good nestled within the body.

At the rear the counterweight blocks are very nicely made, and ten 1.5t pieces are provided with the model which provides the maximum optional counterweight of the real machine. The self raising mechanism is provided with two lift cylinders and chains.

The boom sections are well made and are joined by very tiny brass nuts and bolts which provide an effective connection. The boom foot has a tagline winch to facilitate a clamshell operation, but this is not used on this version of the model. A dragline fairlead is provided and this is a very nicely engineered part, all in metal.

At the boom top a variety of metal pulleys are provided and these are fixed according to the configuration being used. A separate auxiliary jib can be attached for crane operation and this is another high quality part.

The boom pendants are a step in a new modelling direction as they consist of metal wire with crimped loops on each end, and connection pieces. Overall they look effective and the working equaliser balances out the tension in both lines so the model stands right.

Two hooks are provided for crane operation. One is a simple single line headache ball, although this is not the shape of a typical Liebherr hook. The second is a three fall hook block which looks to be a rough version of a Liebherr 50t hook block.

For dragline use, a bucket is provided. This is a great part with high detailing such as the perforations within the bucket, and the chains are nicely painted.

Features

The tracks work well although are a little stiff due to the tension they are under. They are mounted on extendible frames so the tracks can be pulled out in operating mode and can be pushed in to narrow the width for transport purposes. An additional feature is that they are removable by undoing a couple of screws on each frame, so a reduced weight transport mode can be posed.

Four jacks are provided to support the crane when the tracks are removed and these screw down.

The operator's cab tilts to a good angle. The exhaust stack on the roof rotates which means it can be folded for transport which is a nice feature.

There are three winches on the model. One controls the boom and the other two are used for lifting. They are controlled through opening doors on each side of the model, and by using the supplied tools. They all have effective positive brakes which are released by pushing in with the tool, and the winches work very nicely.

The counterweight is fully detachable and configurable at different weights. Special clips are provided to stop the small blocks toppling over and these are reasonably effective.

The model can be configured in a variety of boom lengths and the parts are provided to facilitate either crane or dragline operation so there is no shortage of display possibilities for the collector. This includes being able to show it in different transport modes although the walkways along the side of the crane cannot be folded to minimise the transport width.

Quality

This is a very high quality model which is beautifully made. It is also highly engineered with special care taken to produce a precision model. The paint quality is excellent and the graphics are very good, if simple.

Price

This is a top quality model and is therefore very good value for money.

Overall

This is a first class crawler crane model, which looks great, and sets a very high standard for engineering. NZG and Liebherr can be proud of it. The real machine can be configured in a variety of ways and it is to be hoped that an expansion kit may appear which offers clamshell or foundation equipment which could be attached. Overall this is an outstanding model.

Footnotes

The model first appeared in Liebherr colours at the Nuremberg Toy Fair in 2009 and reached dealers in May 2009. A version in Ballast Nedam colours appeared in 2011 in a run of 300 models..

Assembly Guidance

Small Parts

There are a number of very small parts so it is recommended to build the crane on a tray where dropped parts can be easily found. As items such as the nuts and bolts are brass a magnet will not find them on the floor.

Boom Top Axles T

These have to be fitted and are secured with small yellow clips as shown in the photo at the end of the review.

Pendants

These are formed by inserting the small metal clips inside the larger loops at one end of the pendant. A nut and bolt is used to attach the smaller loop of the adjacent pendant.

Counterweight Pins

See the photo to see how these are secured.

|

| |

|  | | The upper tray. |  | | Two instruction leaflets. |  | | Track details. |  | | Opening door provides access to two of the winches. |  | | Opening door gives access to the boom winch. |  | | Equaliser arrangement is effective at balancing tension in the pendants. |  | | Auxiliary jib and hooks. |  | | Overall look of the model is great. |  | | Lifting beams. |  | | The dragline bucket is very good indeed. |  | | The fairlead is another high quality part. |  | | All on board and ready to go. |  | | The nuts and bolts are tiny and easily lost. |  | | Pendant connections. |

|