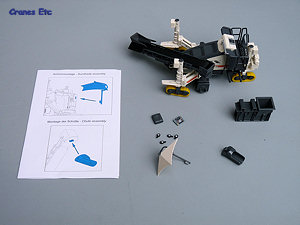

| | Wirtgen branded box. |  |  | | The parts out of the box. |  | | It can stand high, and the mill can be lowered. |  | | Detailed mould box. |  | | The SP 15 being fed by a truck mixer. |

| The Wirtgen SP 15 Slipform Paver was announced at Bauma 2010. It can deal with a paving width of up to 1.80m and a paving thickness of up to 1.30m and the main use of the SP 15 is the paving of concrete profiles in diverse geometries and cross-sections. These include curbs, water gutters, canals, sewers, cable ducts and reinforced traffic barriers as well as special profiles.

Packaging

The SP 15 comes in a Wirtgen branded box, and it is held within two expanded polystyrene trays, and wrapped in soft tissue.

There is no information provided about the real machine. A small leaflet in English and German describes how the various small parts are fitted to the model which only takes a few minutes. Not all features are described however.

Detail

The tracks are yellow rubber and resemble those of the real machine illustrated on the box. They are mounted on smooth cylinder pistons which are contained within detailed hydraulic cylinders although there no hydraulic lines modelled.

The mould is a nicely formed part, mainly in metal, and the trimmer is also detailed with milling wheels and an auger.

The conveyor has a metal frame with a hopper and the rubber belt looks authentic. A metal chute discharges into the mould.

Details on the body are excellent with door hinges reproduced finely and there are textured surfaces on the engine cover. The operator's platform has a textured floor and metal hand rails. The control panels are particularly finely detailed. An umbrella can be mounted and there are spotlights on top of the legs.

Features

The rubber tracks are really too stiff to roll, but the track assembly pivots in each piston, and each leg can be extended by pulling it down and it is stiff enough to hold the model up well. The two front legs cab adjusted for transverse position with the articulated linkage keeping the tracks aligned. At the back the rear leg is also adjustable sideways.

The conveyor belt cannot be moved easily. It can be positioned to discharge on either the right or left side of the machine although it is a little fiddly to move it across.

Underneath, the trimmer has a rotating milling head and auger screw, and it can also be pulled out to extend its reach. It also pulls down significantly for when the machine is standing high on its legs. The mould can be positioned on either side of the machine.

The operator's station can have the control pad positioned on either side and there is also an optional cover which can be fitted. The umbrella can be added or removed as desired.

The model can be posed as a transport load. The mould and umbrella can be removed, and the engine exhaust pipe folds to reduce the headroom if carried on a low loader.

Quality

This is a very high quality little model with plastic used appropriately to enhance the detail.. The paintwork and graphics are very good too.

Price

It is very good value.

Overall

The Wirtgen SP 15 is a finely detailed model with an excellent array of features. NZG have done a very good job with it and it an outstanding model.

Footnotes

The model first appeared as an NZG Winter 2010 release. A version of the model with an auger instead of a conveyor is numbered NZG 8071.

|

| |

|  | | The tray. |  | | Nice rubber conveyor belt. |  | | Very detailed console, here positioned on the right side. |  | | Mould shown on the left side. The rear leg can be positioned side-to-side. |  | | Underneath the body the trimming mill is visible. |

|