| | Liebherr box. |  |  | | The middle tray. |  | | Excellent graphics. |  | | Silver screws securing the boom are visible. |  | | Luffing drums at the rear. |  | | Detailed cab. |  | | Certainly a heavy crawler crane. |  | | Ballast carrier behind the crane. |  | | Heavy derrick. |  | | Profile view with a short main boom. |  | | Lifting using the erection cylinder. |  | | Preparing to be rigged. |

|  Comment on this model. Comment on this model.

The Liebherr LR 1600/2 Crawler Crane can lift a maximum of 600 tonnes at a radius of 11m. It can be configured with a main boom and luffing jib to a maximum under hook height of around 188m.

The crane can be reduced to transportable components for transit between worksites.

The model is in the colours of the German joint venture crane hire company Neeb Schuch.

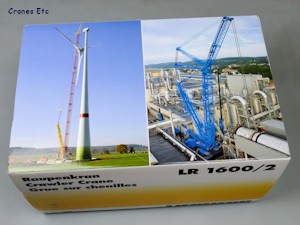

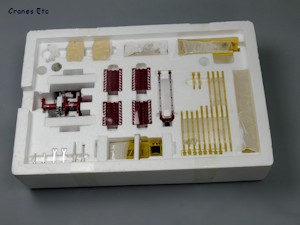

Packaging

The packaging consists of a very large Liebherr-branded picture box which wraps three expanded polystyrene trays. There are many parts and they are beautifully wrapped and protected, so much so that it almost seems a shame to unwrap them.

There were no defects or missing parts on the review model.

There is no information provided about the real crane, but an instruction brochure for the model is included and this has a number of pages. It has the parts in the trays numbered and most are referred to in the assembly diagrams. Good though it is, it does not do the model full justice as it does not indicate some of the configurations that are possible and not all parts are explained. This version of the crane includes a corrected reeving diagram for the A-frame.

Assembly of the crane components takes a few hours as it has many parts but it goes together well. The most time consuming part is reeving and although it is not too difficult it takes time and patience.

One nice aspect is that NZG has helpfully included plenty of spares of the smaller parts such as track links, nuts, bolts and pins.

Detail

The metal track pads are finely made and are mounted on removable track frames which include tiny rollers. Each pad hooks into the next so it is a fiddly job to re-assemble if they come apart but for all practical posing positions the system is fine. Details on the frame are good as well as on the sprockets. A particularly nice detail is the usable lifting shackles.

Between the tracks self-raising jacks are provided although they have visible screw threads, and there are pipes detailed along the frame. The walking platforms have lifting lugs detailed which is a pleasing detail.

The clean lines of the crane body are modelled well, and there is texturing both underneath and on top. Holes to allow the winch drums to be operated are reasonably discreet. At the boom foot there are hydraulic hoses at the slewing motors and a false winch. Metal handrails and platforms add a busy look.

The operator's cab is high quality with a good interior. Externally the cab has lights, aerial, a mirror and windscreen wiper, and access platforms surround it.

At the rear the counterweight blocks are very nicely made and the A-frame has metal pulleys with an erection cylinder included. A nice aspect is the telescopic rams for pushing the A-frame up during erection although as a compromise operation of Winch 1 drum by the key is prevented when the rams are down.

The boom and jib sections are high quality and are joined by tiny brass nuts and bolts which provide a good connection. The boom foot includes a couple of winches and there are walking grilles and metal access platforms which give a realistic look. Boom sections have internal bracing and jib sections can be slid inside boom sections to replicate economic transport loads.

At the boom top metal pulleys are used throughout and the rope retainers are finely engineered. A separate auxiliary lift head can be attached and it is properly hinged so it does not carry the weight of the boom when it is horizontal during erection.

The luffing jib struts are really good with the complex geometry modelled very well. All of the boom and jib guys are excellent. They are metal and look very realistic and are well made to very good tolerances.

The derrick continues the high quality lattice work and there are twin rams at the top for tensioning up the guys to the ballast carrier although the plastic jackets have a mild off-colour look compared to metal parts.

The counterweight trailer is detailed and well engineered. Also the wheels look great and that there are access platforms and ladders.

Two hooks are provided. One has a single pulley and is metal and well made. The second is a large heavy lift hook which is very good and is modular in nature.

Features

The tracks can be rolled but there is too much friction to work by just pushing the crane along. They are mounted on spring loaded sprockets and the track frames are removable allowing them to be used as realistic transport loads.

Four jacks are provided to support the crane when the tracks are removed and these screw down. Pads can be pinned at the ends although the plastic pins supplied would be stronger in metal.

The erection cylinder on the A-frame can be extended.

The operator's cab tilts to a good angle, and it rotates in to a transport position.

There are three winches on the crane body. One controls the A-frame and the other two are used for lifting. They are controlled by using a key and they are sprung with a positive brake action which is very smooth. Additional winches are located on the boom foot and derrick and they work in the same way.

Winch drum 6 on the boom foot can be lowered for transport or pinned in an operational position.

The counterweight is configurable at different weights.

The model can be accurately reeved but with large numbers of rope runs some functions do not unwind naturally unless there is a load on.

The main hook is modular and can be split in two.

The counterweight trailer rolls well and the wheels can be set in towing or slewing mode. The main connection strut to the crane can be set in a variety of lengths but the plastic pins in the strut are a little too loose, so it is better to use spare screws from those provided. The bottom of the access ladder can be folded out of use - another great touch.

At the top of the derrick the guys to the counterweight trailer are joined to hydraulic rams which can be set to the right tension and tightened with locking screws.

Perhaps the best feature of the model is that it can be configured in so many ways. It splits down so it makes great transport loads. Erected, it can be built in many combinations of boom and fly jib, and with or without the derrick and ballast carrier. A really nice touch is that the main lift pulleys are detachable from the lift head and a spare single set of lift pulleys is also provided to give even more possibilities.

Quality

This is a very high quality model which is beautifully made and presented. The engineering is top quality so the parts fit and function well.

The paint quality is excellent and the graphics are very good.

Price

This is a very large high quality model and fully is worth the price.

Overall

This is a first class crawler crane model. It has excellent engineering, very good detail and high quality manufacture which does justice to the Liebherr ethos. This version looks attractive in the colours of Neeb Schuch with the detailed graphics looking great. Overall it is an outstanding model.

Footnotes

The model first appeared in Liebherr colours at the Nuremberg Toy Fair in 2013. This version appeared in Summer 2014 in a run of 300 models, and a run of 600 models in Mammoet colours has been produced.

|

| |

|  | | The lower tray. |  | | The upper tray. |  | | Counterweight stacked up. |  | | Excellent crawler tracks. |  | | Main winch drums. |  | | Short main boom. | |

|  | | Rigged for wind turbine operations. |  | | Lifting a nacelle. Large modular hook has been reconfigured and split, as has the boom head. |  | | Fully rigged counterweight arrangement. | |

|  | | Travelling on site. |

|