|

| Wirtgen branded box. |

|

|

| Profile view. |

|

| Steering in

action. |

|

| Detailed

controls in the cab. |

|

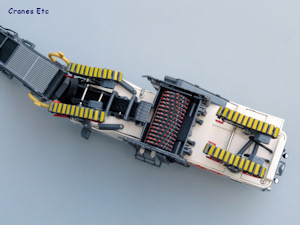

| Metal conveyor

structure.

|

|

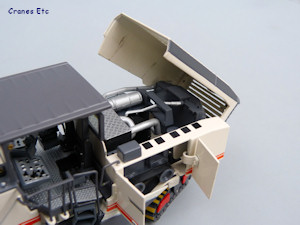

| Engine under

the hood. |

|

| On the road. |

|

| Ready for work. |

|

| Loading a

truck. |

|

Comment on this model. Comment on this model.

The

Wirtgen W 250i Cold Milling Machine weighs around 44 tonnes. It

is used for removing carriageway surfacing in depths up

to 350mm, and can mill to a width 2200mm.

Packaging

The model comes in a Wirtgen branded box and is enclosed

between expanded polystyrene trays.

The review model had no missing parts. One graphic

was slightly misaligned.

The model comes with a bag containing a couple of

handrail parts which have to be fitted at the cab entry

points, and a couple of headrests for the seats. Spare track links are also included.

A small sheet is included which describes some of the

features of the model pictorially, but not all are

covered.

Surprisingly for a Wirtgen Group model, there is no

information about the real machine.

Detail

The metal tracks are finely detailed with yellow

highlighting of the pads, and red scrapers are detailed

too. They are mounted on small frames and

hydraulic hoses run to them from the body.

Underneath the model the milling drum is large with

finely crafted metal picks which are tipped with red

paint. The side skirts are nicely modelled and the

extraction conveyor has a rubber belt.

The engine cover has large see-through grilles

on the top and the detailed twin engines can be seen

underneath with many plastic parts. The main drive belt

for the milling drum is also

modelled in rubber. At the rear the exhaust pipes

have holes and the detailing at the back is enhanced

with lights and a video camera. Each side has

control panels above the legs detailed with paint.

The cab area has non-slip flooring and twin excellent

control consoles with a bank of computer screens.

Thin hand rails look realistic and the windscreens front

and rear are good.

Large mirrors are fixed to the front of the

machine and substantial hoses for the vacuum system run

to the

conveyor.

The conveyor structure is restrained in

height by twin cylinders with realistic thin support

cables. It is metal with a grille underneath and a

rubber belt inside which is realistically textured.

Features

Each track unit has tracks which are stiff, but can be

rotated by hand. They are mounted on pivots at the

end of legs which are extendible to adjust the height of

the machine. Each pair of tracks has linked

steering.

The milling drum rotates and there is an

adjustable side skirt

on each side and a moving scraper plate at the rear.

The cab roof can be lowered to reduce the transport

headroom and the seats have removable headrests to avoid

the rear windscreen clashing.

The main engine compartment

cover can be raised but it does

not pose in an open position. Side panels can be

opened.

The conveyor can be folded to reduce the

transport length. It can be raised and lowered and also

swung from to each side by a reasonable angle.

Quality

This is a high quality model with limited use of

plastic.

The paint and graphics are very good.

Price

It is reasonable value for the size and quality offered.

Overall

This is a highly functional model by NZG, and it is

matched with very good detailing too. It poses well with

other models.

Footnotes

The model first appeared at the BAUMA Exhibition in

2013. |

|

|

|

|

| The model, parts

bag and instruction sheet. |

|

| Detailed tracks

and control console above. |

|

| Big milling

drum with tipped picks. |

|

| Very good

graphics. |

|

| Machine raised

up on its legs.

|

|

| Opening panel

doors. |

|

| Impressive

load. |

|

| Conveyor folded

for transport. |

|