|

| Kleemann branded box. |

|

|

| Profile view. |

|

| Modelled

springs on the pre-screen. |

|

| Opening cover.

Access ladder lowered. |

|

| On the road.

|

|

| Conveyor end

folded lower. |

|

| At work. |

|

Comment on this model. Comment on this model.

Kleemann GmbH is part of the

Wirtgen Group and it manufactures crushers and

screening plant. It has a long history, being founded

in 1857.

The MOBICAT MC 110 Z EVO is a mobile jaw crusher. It

weighs around 43 tonnes and can process up to 300 tonnes/hour.

The machine is aimed at contractors and can be used for

natural stone or recycling.

Packaging

The model comes in a

Kleemann branded box and is enclosed

between expanded polystyrene trays.

The review model had no missing parts or defects.

A small bag contains some spare track links.

The box design is good as panels are used for

information about the real machine as well as good

photographs on the other panels.

Detail

The metal tracks

have triple grouser shoes and the track frames are very

good as for the most part they have working rollers with

a couple fixed on each side.

The rubber discharge belt runs from underneath the body up the conveyor frame which is metal. A

magnetic separator belt hangs from a frame and the

securing rivets used are brass rather friction pins.

The engine cover

is textured with a grille but it is solid rather than

having slots that allow the engine to be seen. A

neat touch is the red emergency stop button below the

engine cover on each side. A metal access ladder

rises to the engine access platform. Inside

opening covers the jaw drive flywheels and drive belt are

modelled.

The feed hopper has a top plastic surface and the detail

underneath is interesting with twin motors to vibrate

the hopper. Underneath the pre-screen is a

transverse rubber belt.

Metal ladders and handrails rise up to the pre-screen

and the crusher jaws are modelled well.

Features

The tracks roll smoothly and are spring loaded to keep

tension.

The

screen on the pre-screener can be lifted off and the

debris cover on top of the jaws can be opened.

The pre-screen conveyor can be stored for transport or

moved into the work position.

The covers on each side can be opened to give access to

the fly wheels and crusher drive belt. The fit of

the doors is not quite perfect though so they do not

close snugly.

The drive belt rotates and it moves the crusher jaws a

little which is a very nice feature.

The access ladder to the middle platform

can be raised or lowered.

The magnetic conveyor can be raised and lowered slightly

and it can be rotated although it is very stiff.

The main conveyor belt can be rotated, and the end can

be folded to lower the transport headroom.

Quality

This is a good quality model with

a high metal content.

The paint is very good and the graphics are sharp.

Price

It is reasonable value.

Overall

NZG continues to produce high quality replicas for the

Wirtgen Group and this Kleemann crusher is a good

example. The build quality of the opening doors

was not top notch on the review model, but overall it is

easy to highly recommend.

Footnotes

The model first appeared at the BAUMA Exhibition in

2013. |

|

|

|

|

| Motors under

the hopper. |

|

| Full length

conveyor. |

|

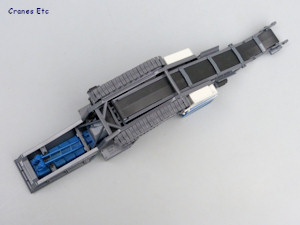

| Flywheel and

drive belt. |

|

| Pre-screen

removed and cover to the jaws open. |

|

| Conveyor

unfolded ready for work.

|

|

| Loading the

crusher. |

|

| Rocks in the

jaws. |

|