| | Vermeer box. |  |  | | The parts out of the box. |  | | Opening hood reveals a detailed engine. |  | | Extreme detail behind the cab. |  | | The complete haulage combination. |  | | Underneath the Tub Grinder. |  | | The Tub Grinder being set up for use. The cones are supplied with the model. |  | | The cab, with opening door. |  | | Opening doors. |  | | Inside the tub. |  | | Whatever grabs you. The grab edges are serrated to grip on to any trees reluctant to go to the tub. |  | | Grab structure is very detailed, with first class hydraulics. |

| Vermeer was founded in Iowa USA in 1948 and is now a manufacturer of agricultural and excavation equipment.

The TG7000 Tub Grinder is a powerful machine for large land clearing projects and organic/wood waste processing applications. It features a cutting drum which can mulch trees into fine material. The machine weighs nearly 85,000lbs (32t) and features a Caterpillar 3412E engine. The conveyor system is designed to have a running speed approaching 15 feet/second (4m/s).

Packaging

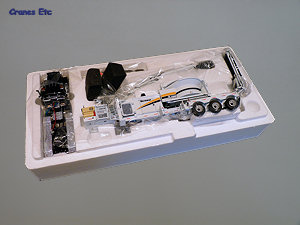

The model comes in a Vermeer-style picture sleeve box, and is securely packed within a pair of expanded polystyrene trays and wrapped with polythene sheets. The packaging works well as although there are many small and delicate parts there were no defects or missing parts on the review model.

Two small brochures are supplied. The first is a print of a marketing leaflet for the real machine which includes the specifications, and this is a welcome inclusion with the model. The second is a nice colourful set of very good assembly instructions which describe how to display the model in transport or functional mode. There are a few small parts to fit, but this is very easily accomplished.

A plastic pointer tool is provided to ease the opening of doors on the model.

Detail

The tub grinder is a highly detailed piece of modelling, and indeed this is one of the most detailed models seen by Cranes Etc at the time of the review.

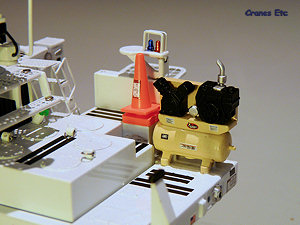

Underneath, the axle suspension is replicated with cabling liberally sprinkled to the axles, and under the engine block. At the front, there is a compressor unit finely detailed in plastic, and a cone storage area where the supplied cones can be stacked. Forward of this there is a first class control panel which looks so good it seems to be ready to be powered up, and it is protected by fine quality metal safety grilles. Detail within the castings has various access covers replicated, complete with securing bolts.

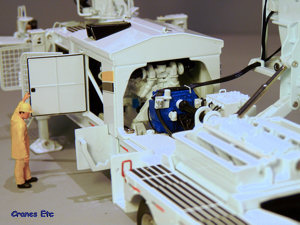

Very fine mesh steps lead up to the control cab, and the adjacent metal outriggers are nicely modelled with the only weak point being that some of the securing rivets are silver rather than painted and this detracts from the look slightly. The roof of the engine enclosure has very fine lifting eyes provided and this detail is provided elsewhere on the model also. Inside, the engine is detailed with hosing and pipe work, and by looking carefully a detailed fan can be seen.

The tub is a metal casting and has a rubber belt to simulate the chain drive for rotating the tub. A pivoting tub cover assembly provides safety protection for objects thrown by the violence and power of the tub operation. At the bottom of the tub the cutting drum is replicated complete with hammers and cutters, and there are separate screens.

The underside of the tub structure is finely modelled and is complete with hosing to the drive motors. The excellent detail level continues with the motor drive to the cutter drum which has cabling and other small details. A very nice three stage hydraulic cylinder props open the tub to provide access to the cutter drum. The conveyor has a patterned belt and looks really good. The hydraulic cylinders and drive motors all have hosing running to them which enhances the look of the model.

At the rear of the tub grinder, the lights are painted and there are some rubber mud flaps. A couple of steps and two very fine metal grab rails provide a means of access the bed of the trailer which has non-slip strips on the surface.

The grab machine maintains the overall detail level of the model. Excellent mesh steps lead to the cab and this has a very thin grab rail and an excellent mesh screen on the windscreen. The inside of the door has tiny safety notices, and the controls within the cab are modelled well, and includes a small red fire extinguisher. The grab boom is very detailed with hydraulic hosing connecting to separate silver pipes fixed to the structure. This is perhaps some of the finest modelling of hydraulics yet seen on a mass produced 1:50 scale model. The grab is metal and cast very well and it is only here that the silver rivets used are somewhat obtrusive and would have been much better painted.

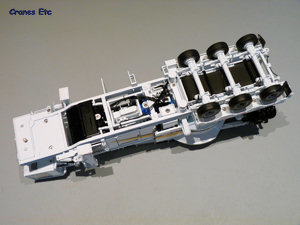

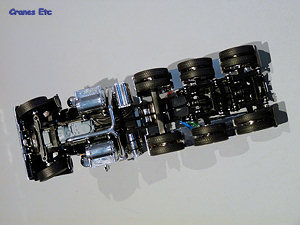

Turning to the Peterbilt 379, the chassis is very detailed underneath. The two driving axles are complete with prop shafts and differentials and replicated suspension details, and there is a third helper axle. The rear wheels have very good metal hubs with finely treaded tyres, and there are rubber mud flaps bearing the Peterbilt logo.

Towards the front the underside of the engine is visible and the exhaust pipes lead out to the side of the body. The front tyres are different from those at the rear, are on different metal hubs also.

The imposing front of the Peterbilt is modelled very well with a superb finely etched radiator grille, with a spoiler on top. The bumper is metal and the headlight clusters have lenses incorporated for the headlamps. Both on the top of the radiator and on the sides of the hood (bonnet) there are tiny Peterbilt badges which are perfectly legible. There are excellent rubber mud flaps behind the wheels. Under the bonnet is a detailed engine, with a separate radiator, and there are various pipes and hoses modelled.

The cab detail is all of an excellent standard. On each side fuel tanks with very fine graphics are modelled and they are integral with the cab steps which have nicely patterned treads. There are a pair of exhaust stacks and each has a grab handle and the exhaust pipes have holes at the end and therefore they actually look like pipes. Around the top of the cab there is lots of chrome work with very good metal wing mirrors, lights and air horns. The two orange beacon lights on the roof of the cab add to the look but there is no 'glass' in the cab windows which is not so good. Inside, the cab is also detailed with the steering column having a tiny stalk below the wheel and fine details on the inside of the door.

Behind the cab, the detail continues with three coiled lines for connection to the trailer. There are also some fine chains and equipment including a replicated piece of folded tarpaulin.

Features

Each axle on the Tub Grinder has working suspension and there are four outriggers. The two at the rear in front of the axles just pull down into position whilst the two front outriggers have hinged pads which can be fixed in either a lowered or raised position.

There are numerous opening doors on the model. A pair of mesh frames provide protection to the control panel area, and there are four opening doors in the engine area. The door of the operator's cab also opens. To provide access there are two sets of folding steps

The tub grinder has high functionality. The cutter drum rotates and this includes its drive shaft, and the whole tub rotates. The tub cover is fully hinged and can be moved into a travelling position. In fact the whole tub grinder assembly can be opened up to provide access to the cutter drum and screens.

At the rear, the conveyor belt moves smoothly, and the whole arrangement is hinged so that it can be folded for transport.

The grab structure rotates, and the boom can move into any position and the cylinders are stiff enough to hold a pose. The grab opens and closes, and also swivels on its attachment to the boom.

The front wheels on the Peterbilt steer, but the steering is 'notched' rather than variable so the wheels can only be posed in one position when pointing left or right. The helper axle can be clipped out of use and this is achieved by removing the cover above the axle and adjusting a screw so this provides a variety of display options. The hood opens in a very easy action and the cab doors can be opened too. The ‘fifth wheel’ on the tractor works and is operated with a spring loaded lever to secure a trailer in position. It can also be adjusted longitudinally.

Quality

This is a very good quality model which is made very well and uses plastic both sparingly and appropriately. The paintwork and some of the tiny graphics are also very good.

Price

This model is very good value given the overall high quality and functionality.

Overall

In some respects this model of the Vermeer Tub Grinder sets a new standard for high detail, and this is well matched by the features included. There are some minor areas for improvement, with painted rivets being one such area. Overall however, this is an outstanding model.

Footnotes

The model first appeared at dealers in May 2009. The run of the model is 4000 units. The TG7000 was produced in the following versions:

Vermeer yellow, 3250 units

White, 375 units

Green, 375 units

|

| |

|  | | The model sits in the tray. |  | | The Peterbilt 379 Day Cab. |  | | Opening door on the cab, and plenty of chrome. |  | | Underneath the Peterbilt. |  | | Rear view. |  | | Suspension on the rear axles has a good range of movement. The rear outriggers are just in front of the axles. |  | | Very detailed control panel looks like it should work! The operator is protected from flying objects by two grilles and there is a fire extinguisher for when things get fiery. |  | | The tub opens up to provide access to the cutter drum. |  | | Detailed engine block resides within the body. |  | | Conveyor is excellent. |  | | Tiny details on the compressor. |

|