|

| The box for the

carrier. |

|

|

| The box for the

boom sections. |

|

| The parts from

the carrier box. |

|

| The carrier.

|

|

| It makes a good

display model just like this. |

|

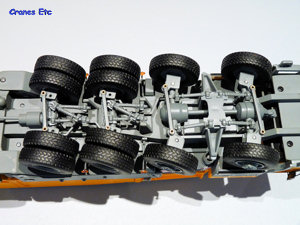

| The chassis is

superbly detailed. |

|

| Close up of the

intricate steering and suspension details. |

|

| The boom foot on

a Talbert

Trailer. |

|

| The counterweight

slabs have the name and weight within the casting. |

|

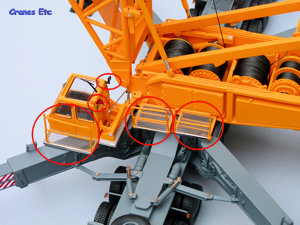

| Excellent details

between the outrigger beams. The ladder is a nice

touch. |

|

| A

Liebherr

LTM1200-5.1 helps build the boom. |

|

| The counterweight

slabs have chains to secure them. |

|

| Mesh walkways allow

the Cranes Etc team to act tough and walk the high steel.

|

|

| Tilting cab for

the high lifts. |

|

| Beautifully made

rooster head section. |

|

| Excellent straight

boom and pendants. |

|

Small parts that

have to be fitted. On the left the red chain is pinned

in a small holder and fed through the hole in the counterweights

to secure them. In the centre the access platform

is fitted. Also the hydraulic cables from the boom

winch are fed through the side of the boom foot and plug

into the side of the body.

On the right the spare wheel winch is fitted. Two

of the four wheel chocks are shown placed in a holder at

the rear. It is also worth noting the position of

the equaliser at the back of the crane. This is located

between the inner and outer sets of ropes for the moving

mast. |

|

| From left to right:

a handrail is fitted outside the cab. Two lights are

fitted to the cab roof. Two access platforms are fitted

to the side of the body. |

|

The Liebherr LG1550 is a very versatile

lattice boom mobile crane which has a maximum capacity of

550 tonnes and can lift to heights of up to 180m.

The flexibility comes from the range of boom options available

including two types of luffing fly jib, and a derrick.

The carrier for the crane is 8-axle, and is a shared design

with that used on the LTM1800 telescopic boom crane.

One of the many applications for the crane is in the erection

of wind power systems. The crane has four of the eight

axles fitted with twin tyres meaning that 24 wheels can

carry the load of the crane enabling it to move on site

with much of the equipment and ballast loaded.

Packaging

Unusually, the model comes in two boxes. They are

surrounded by foam and packed within a larger cardboard

box. The quality of the packing is exemplary and gives

the feeling of high quality long before the model is reached.

The two picture box sleeves are in a typical Liebherr style

design-wise, but these are just covers to a high quality

plain boxes which contain the parts of the model.

When these are opened the model is contained within more

black foam rubber, and each piece is individually wrapped

in soft paper. And it gets even better. The carrier

sits in its own plastic tray and thoughtfully this is placed

in the foam rubber with red ribbon underneath, which, when

pulled, lifts the model out easily. The same technique

is used for the boom parts as well. There were no

defects or missing parts on the review model.

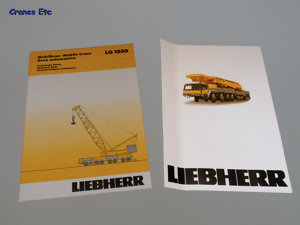

Two brochures are included. The first deals with the

carrier and has extracts from Liebherr technical information

and explains the boom hoist reeving. There is a list

of small parts but not all of their fitting is shown.

The second is a reprint of Liebherr technical data, complete

with loading charts, and also deals with the boom parts

and contains clear reeving diagrams. Although initially

it seems strange that the model packaging and brochures

are split in two, it does mean that at some point in the

future the boom system could be sold as a separate part

by YCC enabling owners of the YCC LTM1800 model to convert

to a lattice boom version if they wish. Similarly,

perhaps the telescopic boom of the LTM1800 could be sold

separately for LG1550 owners.

Assembly of the model is quite straightforward. The

brochures describe the main information well but leave out

some of the smaller parts. To help collectors, the

fitting of these and other parts is described in the

Assembly Guidance section below.

Depending on the configuration, a few hours should be allowed

to build the model, and as usual the slowest part is reeving

the model where, as always, patience and a methodical approach

is needed.

Detail

There is no doubt that at the time of the review this is

one of the most detailed crane models reviewed by Cranes

Etc.

The underside of the carrier is excellent with very good

transmission and suspension components detailed, and they

all in metal too. In fact the overall structure of

the chassis is modelled in a very convincing fashion and

it is almost a shame that in normal poses it cannot be seen.

The metal wheel hubs look very good, being of two types

as per the original, and mounted with excellent tyres bearing

the ĎMicheliní logo on the outside.

The driving cab has very finely made windscreen wipers and

mirrors, and the towing hitch at the front is of a realistic

size. Steps to the cab have a fine texture and the

cab is completed with excellent lights and double air horns.

The air horns have to be fitted and rest loosely on holders.

A tiny sign is on the cab side windows. Detail behind

the cab continues at an excellent level. Two tiny

grilles are present behind the driverís door, and the covers

to the engine block have superb mesh detailing. The

metal chromed exhaust is formed to have holes in the exhaust

pipes. More mesh work leads to the slewing ring and

here hydraulic cabling runs to the outrigger beams.

Alongside the body on both sides are small orange lights

which sit at the end of thin stalks. At the rear the

hydraulic details for the outrigger beams are present as

for the front pair, and there is a spare wheel with lifting

gantry, a holder for tiny wheel chocks (which are complete

with lifting handles) and the light bars have nice plastic

lenses.

The outrigger beams are beautifully made. The inner

sections have excellent hydraulic line details within the

castings and the two stage beams are metal and feel very

solid. At the end the pistons screw down to the transverse

pad beams without revealing any unsightly screw thread.

The spreader beams and pads are first class. They

are all metal and very well detailed. Better still,

they contain magnets which allow the pads to stick to the

beams and the beams to stick to the pistons which is really

an excellent design. The only minor criticism that

can be made is that the rivets connecting certain parts

are silver and would look better if they matched the painted

colour of the parts concerned.

The high quality continues into the crane body. The

cab windows have fine seals and windscreen wipers.

Inside, the controls are clearly seen, and outside there

are excellent grab rails and mesh walkways. Alongside

the body the panels have fine details within the casting

including hydraulic lines. Inside the body the winch

drums are well detailed, with some very fine diamond patterned

plate work. The pulleys used are metal and are painted

to match the crane colour so look very good indeed.

The boom gantry is raised by excellent metal three stage

cylinders which have ingenious magnet connections to the

gantry. At the gantry head there is a hydraulic lift

cylinder and top quality metal pendant connections.

On each side of the body some access platforms can be fitted

when the crane is being used. These have very good

mesh floors, although the hand rails are plastic and because

they are thin, they are delicate. These parts press

fit into holes in the body which means they are easily knocked

off if handled.

The counterweight tray has lifting points cast in and the

counterweight slabs are first rate also, with each one having

excellent lifting points and the Liebherr name and weight

clearly visible within the casting detail. Two sets

of chains and associated clips and pins are provided to

enable the counterweight slabs to be secured, and these

add to the detail. A pair of plastic ladders is also provided

with the carrier which is a nice touch for posing the crane

in use.

Moving on to the boom sections the model makerís skill continues

to be evident. The boom butt section has a wealth

of fine metal mesh walkways and there are very nice rollers

for allowing ropes to run smoothly. Two small spools

are contained within the boom section and there is hydraulic

cabling running from the winch which can be secured into

the body. The boom connections at the end are very

fine as are the small bolts used for joining the sections.

The straight boom sections are similar quality being dead

straight, and with mesh walkways and internal bracing. The

smaller LI boom sections fit nicely inside the S boom sections

so simulating accurate transport loads is possible.

Two boom head sections are provided with either 16 or 4

pulley sheaves. Once again the detail level is excellent

with metal pulleys throughout. Even the short reducer

boom section has a working roller, and eyes for fitting

a direct connection to the pendants for long boom lengths,

and the connectors are supplied with the model. Also

included is a rooster head and this difficult section is

superbly made with a folding line pulley and tiny rollers

to enable this piece to roll on the ground if needed during

erection.

The pendants are very finely made. All in metal, they

look extremely convincing and use very small plastic split

pin bolts, similar to those used to join boom sections.

On the review model one pendant line was very slightly slacker

than the other but this was barely visible.

Three hook blocks are supplied with the model and this approach

is to be particularly commended as it gives the collector

flexibility in rigging the crane. They are nominally

15 sheaves (350t), 9 sheaves (235t) and 3 sheaves (93t).

Each one is excellent in its own right and would look great

on any Liebherr crane model. They have metal sheaves

and very good hooks complete with safety catches.

Features

The steering on the carrier is good with axles 1 to 4 and

7 and 8 steering like the original. A reasonable lock

can be obtained although perhaps not as much as the real

crane can achieve.

The outrigger beams pull out laterally from the carrier

to form a star shape and can be telescoped out smoothly

to maximum extension or alternatively the model can be posed

with shortened outrigger beams like the original.

The pistons screw down smoothly to replicate a pinned bearing

connection on the transverse beams.

The crane cab is a swing away type which tucks in at the

front when in transport mode. It can also be tilted

to allow the operator comfort when the crane is lifting

at height. A working hydraulic hook is provided on

the moving mast and it is stiff enough to hold a reasonable

load.

The crane rotates smoothly, even under load.

The crane body has four winch drums and these are accessed

by using removable magnetic side panels on the body.

This excellent design feature allows the model to be operated

without having unsightly access holes in the side of the

body. Each winch is stiff enough to hold any reasonable

load, and they are can be operated by using a special tool

which has a screwdriver connection at the end so it can

be driven by a powered screwdriver which is useful for loading

the drums with the supplied thread. A fifth winch

is contained within the boom foot section and this can be

operated in the same manner.

A strong feature of the model is that it is made in the

modular system which replicates the real machine.

This means it is possible to configure the model in many

different arrangements of boom and counterweights and so

it is possible for a collector to display the model any

way they want.

Quality

This is one of the very best quality models seen by Cranes

Etc as at the date of the review. The standard of

detailing is first class and there is hardly any plastic

used. In fact it makes any of the plastic pieces that

are used feel a little out of place. The standard

of the casting is also very high.

The paintwork is very good although on the review model

there were just the slightest of differences in colour between

some parts. In part this may be explained by the different

paint used on the boom sections and the carrier, with the

carrier paint being more gloss-like, and the boom parts

having a slightly more matt texture. The quality of

the applied graphics is very good.

Price

A model such as this is not aimed at the cheap end of the

market, and it is all the better for it. Rather the

approach has been to aim for a standard of excellence and

achieve it, and with this in mind it is very good value

for money.

Overall

This model from YCC sets the highest of standards in mobile

crane models and both YCC and Liebherr can be proud of it.

Any collector wanting the very best in scale model cranes

does not need to look much further than this. In fact

given the limited production runs of these models, they

are may be a good long term investment, particularly those

in company liveries.

In some respects this model is close to a work of art and

there is no question about it, this model easily deserves

an 'Outstanding' rating.

Footnotes

The model first appeared as a prototype at the Nuremberg

Toy Fair in February 2008 and it appeared at dealers from

January 2009. A version in Wiesbauer livery became

available in January 2010 in a run of 80 models. Additional

boom sections are available as YCC part number 781.

The luffing fly jib, part number YCC 771, can be fitted

to the model, and a derrick mast, YCC 772, can also be fitted.

Assembly

Guidance

For assembly of small parts refer to the photos.

When assembling the boom sections an easier fit of pins

is achieved if a little of the paint inside the connections

is removed by gentle scraping with a small screwdriver.

Before attaching the access platforms to each side of the

model it is better to remove the paint from inside the holes

to enable a better fit.

During reeving of the boom hoist, it is necessary to get

the two separate lines of approximately the same length

so that the equaliser only has to deal with differences

caused by the way thread is spooled on the drums.

The best way to do this is to open up the moving mast fully

and reeve one half fully but leave it untied on the equaliser.

Then reeve the second half and tie both lines off at the

equaliser so they are of equal tension and the equaliser

is level.

To reeve the hooks it can be helpful to cover an amount

at the end of the thread with some glue to stiffen it up

and make it easier to push through gaps. Before starting

the reeving, spool out enough thread to be able to complete

the reeving. As the thread is passed through the safety

pin on each side of the hook block, fix it in place using

a piece of plastic putty to stop it bouncing off later.

|

|

|

|

|

| The carrier box

is top quality with foam rubber, and ribbons to enable the

model to be lifted out. |

|

| Two brochures,

one for the boom (on the left), one for the carrier.

|

|

| The parts from

the boom box. |

|

| Fine details at

the rear. |

|

| The steering shown

at about the maximum lock. |

|

| The attention to

detail is shown by the very small sign on the cab window

and the grilles adjacent to the Liebherr sign above the

front wheel. The tyres have 'Michelin' on

them. |

|

| With the right

transport vehicles, a good display of the crane on the road

can be made. |

|

| Boom head and reducer

section. |

|

| The crane being

rigged. |

|

| Placing a counterweight

slab. |

|

| Outrigger beam,

spreader bar and pads are all first rate. |

|

| Three hooks are

supplied. |

|

| The pendant bars

are highly detailed, and the securing bolts are split pins

of a realistic size. |

|

| Load testing the

LG1550 with another new delivery into the Cranes Etc fleet.

|

|

| The reducer section

and pendants. |

|

| Fully rigged with

all the boom sections, the crane lifts a tank high. |

|

| The design of the

side body panels is ingenious. They are held by magnets

so to access the winch drums they are simply removed.

When the model is posed the panels are replaced and the

model is not spoiled by holes in the side of the body.

|

|

| Air horns are placed

on the driving cab roof and the pistons have to be screwed

into the front outriggers only. |

|