|

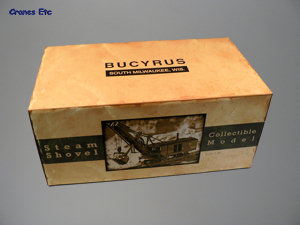

| The 'aged' box. |

|

|

| All the parts out of the

box. |

|

|

|

|

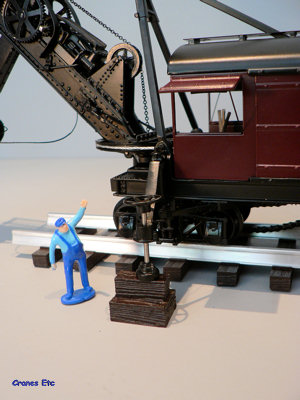

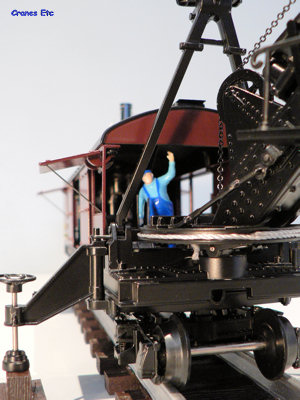

Screw jack and blocks of

'wood'. The control levers are visible in the cabin. |

|

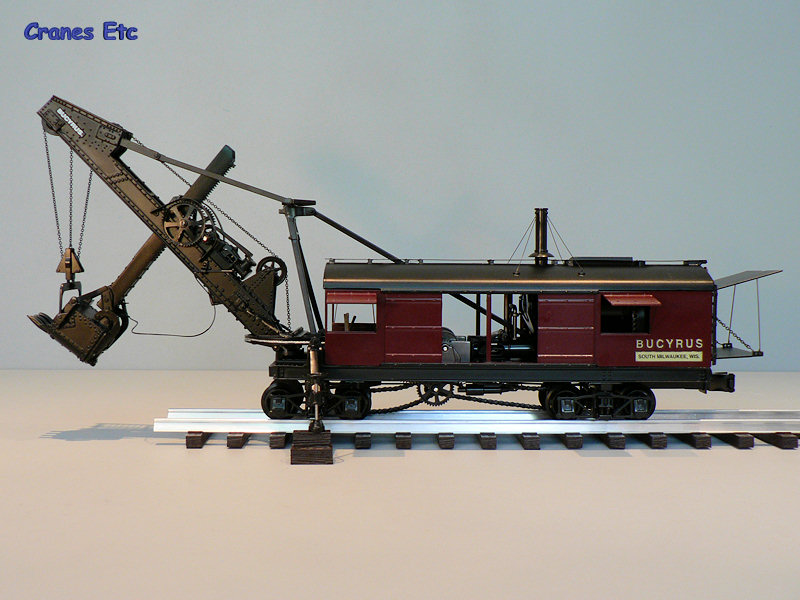

| Profile view. |

|

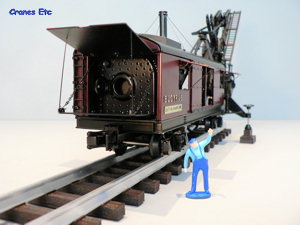

| Opening coal door on the

boiler. |

|

| Excellent shovel gear.

|

|

| Authentic heavy looking

structure for the digging machinery. |

|

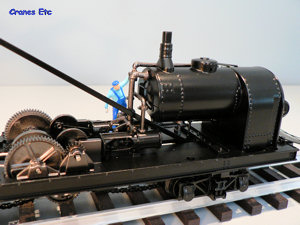

| Superb boiler details.

|

|

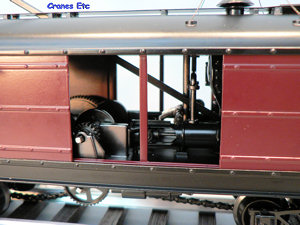

| Metal gear mechanisms.

|

|

The Bucyrus Company has a long history.

It was founded in Bucyrus, Ohio in 1880 and thirteen years later

moved to South Milwaukee, Wisconsin. Soon after it decided

to specialise in excavating machinery.

Around the turn of the century the 95-ton steam shovel was the largest

the company built and they were used on many projects and Bucyrus

shovels were the most prevalent in use during the construction of

the Panama Canal.

This model was commissioned by Toy Trucker and Contractor Magazine

and is in 1:48 scale. As a rail mounted piece of equipment,

the scale has been chosen as it is 'O' gauge, and so could find

a place onto a suitable railroad layout although the model is not

designed to be towed behind an engine.

Packaging

The model comes in a box which has an aged appearance and so suitably

represents the historic nature of the model it contains. Inside,

the model is securely packed between the usual expanded polystyrene

trays. The review model had no defects or missing parts.

A small booklet details the history of the Bucyrus company and has

interesting photos and narrative about the real machine. Two

small cards are also provided. One warns that the model is

designed for static display, and the other has some small photos

illustrating the basics of assembling the few pieces that need it.

Although it is good that these instructions are provided, they do

not do justice to the model itself. TWH have recognised this

and they have produced an updated set of instructions which can

be downloaded - see the Model Notes section at the end of this review.

Care is needed to unpack the model as the drive chains under the

carriage are taped together and need to be carefully removed before

doing anything else.

Detail

On looking at this model for the first time it is clear that it

is something special.

A length of track is provided which has metal rails (which look

a little oversize) and plastic

ties (sleepers) which look like wood. In addition two plastic moulded blocks for packing under the outriggers are provided.

These look like timbers and it would have been nice if they had

consisted of separate pieces rather than one piece.

The underside of the model gives a taste of the detail and engineering

quality that is this model. Drive chains lead from sprockets

to the bogies. These have fine flanged wheels with excellently

detailed bogie frames and suspension. At the front end of

the car frame are outriggers, one on each side. These have

fine structural elements, and at the top a nice spoked turning wheel.

The machine house sits on the car frame and has rivet details to

all doors and windows. The Bucyrus nameplate is embossed beautifully

within the casting. At the rear there is a ladder to the roof

complete with turning handle, and the roof has rivet details with

a chimney stack that has realistic stays to hold it in place.

At the front the digging equipment is very detailed with rivet details

authentically representing the real structure of the shovel.

The boom turntable is a crafted piece of model engineering, and

the main boom is stabilised at the bottom by replica turnbuckles.

Steel coloured string is used in the mechanism to rotate the boom

from side to side. The only compromise to high quality detail

is at the top of the boom support where a black crosshead screw

is visible. A ladder extends up the boom, and there is a platform

with handrails for the dipper flap operator. Excellent guards

cover the toothed gears which drive the dipper handle. Black

chains are used to raise the dipper and these run on excellent metal

pulleys. The dipper itself is very finely modelled with rivet

details and good looking teeth.

To fully appreciate the detail in this model, you need to look inside

the machine house and the best way to achieve this is to remove

it. With the house off, the quality of the model can be further

appreciated. At the rear of the car frame is a coupling mechanism

for connection to other rail vehicles. The boiler area is

tremendous, with excellent pipe work including tiny valves, and

riveted boiler construction. The engineering complexity of

the model is fully apparent with the working gear and piston arrangements,

all in metal. At the front of the model is a bank of operator control

levers.

Features

The shovel can be moved along the track by inserting and winding

one of the supplied keys under the car frame. This works the

sprockets and chains and moves the vehicle smoothly. The bogies

have fully working suspension which use tiny springs mounted between

the axles.

The coupling mechanism at the back is spring loaded and works.

On each side the outrigger beams swing out and are locked into place,

allowing the pads to be screwed down to stabilise the shovel during

digging operations.

The machine house has opening sliding doors on both sides and opening

windows which can be realistically propped open. At the rear

the coal loading deck opens and is supported on chains and props

are used to hold up the rear flap to form a roof.

The boiler coal door opens. Inside the cab, the control levers

can be moved and set to different positions.

Using a key the main shovel functions can be operated. The

boom can be moved from side to side and the dipper raised and lowered.

Operating these functions causes the steam pistons inside the house

to work which is a first class feature. The crowd action on

the dipper handle can be achieved by using a key on a pinion on

the main boom which drives a rack on the dipper handle to extend

and retract it. The flap of the dipper can be opened using

the release cable.

To have full sight of the internal detail, the house needs to be

removed from the car frame. TWH do not recommend this, but

in practice it is straightforward to undo eight screws, detach the

boom support strap and chimney, and ease the house off making sure

the sliding doors do not fall out onto a hard surface and get damaged.

Quality

This model is among the very best Cranes Etc has seen at the time

of the review. The detail and engineering are top notch and

there is hardly any plastic used. The paintwork and quality

of finish is excellent.

Price

A model such as this cannot be expected to be inexpensive.

However it is very good value for a model of this quality.

Overall

This is one of those few models that is such a quality item that

almost anyone would be happy to have it on a mantelpiece, even if

they have no interest in collecting models, or the machine itself.

The detail and features are excellent, and the quality is first

class. Hopefully some day all quality models will be made

this way.

Footnotes

The model first appeared in 2007. The run of the model is

3000. An updated instruction sheet has been produced for this

model and is available for download

here (964Kb).

|

|

|

|

|

| Inside the box. |

|

| First class model engineering

visible inside the machine house. |

|

| Excellent rivet details.

|

|

| Chain drive to the bogie

and delicate stays hold the chimney. |

|

|

|

| Opening flap on the dipper.

|

|

| Taking the house off reveals

first class detail and engineering. |

|

| Excellent engineering is

the hallmark. |

|

| Underside view showing

the chain drives. |

|

| As good as it gets.

Boiler and pipe work detailing. |

|