|

| Inside each of

the two massive cartons is a sleeved box. |

|

|

| Middle layer -

Carton 1. |

|

| Top layer - Carton

2. |

|

| The ring plates

are individual pieces. |

|

| A

Haulotte HA20

PX assists in attending to one of the bogies. |

|

| A

Manitowoc 555

dreams of lifting a boom section off a

Nooteboom trailer.

|

|

| Just compare.

|

|

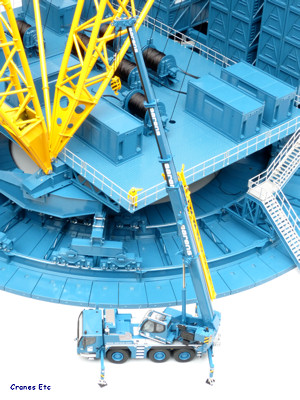

| Upper deck is

clean and tidy. |

|

| Boom section compared

to a truck crane. |

|

| The A frame mounted.

|

|

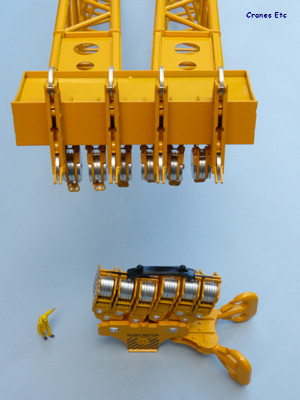

| Ready for reeving

up. It could be a long night. |

|

| Large metal

pulleys on the A-frame. |

|

| Loaded containers

all on board. |

|

| Detailed

access stairs. |

|

| A massive

crane model. |

|

| Impressive

heavy boom. |

|

| A Liebherr LTM

1050-3.1 is somewhat overwhelmed. |

|

The Sarens SGC-120 is a giant ring crane

with a lifting capacity of 3200 tonnes. It has been

designed for use in petrochemical, nuclear and other engineering

activities where heavy lifting is the requirement.

It can lift 3200t at 30m radius and 1000t at 80m.

The real crane has a 130m main boom and a 90m light duty

jib can be fitted.

Among the interesting statistics for this crane is the weight

of the hook block at 105 tonnes and the ballast is provided

by locally sourced material in 36 40ft shipping containers

to produce 3600t of ballast. The entire crane can

be shipped in around 135 standard containers. It takes

one hour for the crane to rotate through one revolution.

This scale model is enormous. It is configured with

the main boom only but laid out the overall length of the

model is 3.3m long. With the boom up it reaches 2.6m

and the diameter of the ring to the edge of the spreaders

is nearly 90cm.

Packaging

The model comes in two very large cartons measuring 92x91x29cm

and weighing approximately 26 and 22kg. Each contains

another box with a colourful Sarens sleeve on the outside.

Because of the size the sleeve is most easily cut off rather

than trying to push the inner box out.

Inside the boxes the model parts are packed in layers with

the boom sections tied to cardboard bases. This works

well in terms of protecting the parts (particularly as the

outer boxes had some shipping damage), but if you want to

keep the ties for re-use in packing the model it is a painstaking

exercise to release them and free the parts.

There were no defects or missing parts other than one container

cross-tie which had not been cast properly but this was very minor

and was to be replaced by WSI.

There were no instructions included in the box, and these

were supplied separately, and are also available for

download. The instructions are clear and good with only

the main reeving diagram having some small conflicts.

The two bolts that secure the main boom are a little too

short to tighten the nuts properly but this is not a problem

as the bolts are very unlikely to move.

There is is no information about the real SGC-120 which

is an opportunity missed, and a uniquely numbered collector's

card would have given a special feeling.

Unpacking and assembly is not difficult although some operations really

need two people at least and a day should be set aside. Reeving the hook and luffing

winches is time consuming and requires considerable patience

and a calm temperament.

One interesting aspect is that the model

does not come with loaded ballast. Instead the containers

are empty and need to be filled with sand or other material.

This is a sensible modelling decision by WSI as it reduces

the shipping weight while at the same time reflecting the

philosophy of the real crane.

Detail

An interesting aspect of the model is that much of it is

preassembled. The ring with the ground bearing plates

is all prefabricated in the box and accounts for the packaging

size. However closer inspection suggests it can be

split into smaller appropriate pieces by undoing screws.

The ring is all metal and includes detailed lattice sections.

Four bogies are mounted on the ring track, two at the front

(with more rollers) and two at the back. These are very

large pieces with suitably strong metal beams. Unlike

much of the model there are some riveted connections

so it is not so easy to break the bogies down into transport

loads. Each roller has a plastic motor modelled although there

are no cables running to the plastic control frame.

The upper structure is very big, but simple in design

and detail as it reflects the uncomplicated design of the

real crane. The structure looks great with realistic

beams and the deck surface has an anti-slip surface.

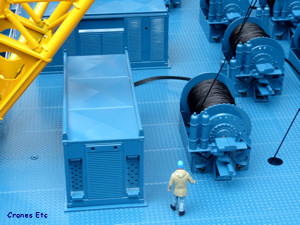

Six large detailed winches are mounted on the deck together

with seven metal containers, and there are hydraulic lines

running between them. The handrails are metal and

there are two sets of excellent metal staircases to provide

access to the deck. There is nothing by way of graphics

around the deck area and the two holes in the deck for the

luffing rope equaliser look odd without some protection

or guarding around them. Underneath the deck there

are two pulleys which are used for the luffing rope equaliser.

These are plastic non-functioning parts which although they

will be rarely seen is something of a modelling compromise,

and they did not seem to properly align on the review

model.

A small plastic cabin provides the operator's area.

It is well detailed inside with controls, screen, cabinet

and seat and it would have been nice if it had lifting eyes

so it could be posed being lifted. Such is the size

of the crane that the cabin looks lost on the massive machine

deck.

At the rear of the upper deck there are 36 ballast containers.

These are made of tough plastic which is the right material

given that they get filled with sand or stones and fortunately

they have a very good colour match. Metal cross ties

add strength and allow good stacking although as provided

the containers cannot be posed being lifted by a crane unless

the cross ties are glued in. Four of the containers

are emblazoned with the Sarens name.

The main A frame is made of huge parts. The rear

ties are about 20cm square and are heavy. The main

struts are giant lattice sections 10cm x 5cm at the widest

with member sizes around 8mm thick. This is massive

size model engineering and is very impressive on its own.

At the top of the A-frame are large silver metal pulleys

for the hook and boom luffing ropes.

The boom sections are the same dimensions as the A-frame

parts and the whole boom is therefore massive, well made

and strong. It consists of small discrete sections

which are screwed together and the structure of each is

very good with all lattice chord members tubular in

section. At the boom head are large banks of pulleys

for the hook

ropes.

The main boom guy ropes have metal connectors and look good

with good manufacture meaning that the tensions in the parts

look broadly equal with nothing sagging.

The hook block is very large and heavy, and includes a huge

pair of double hooks with latches. It is very well

detailed with excellent graphics and this makes a

great model on its own.

Features

The real SGC-120 is designed to be broken down into container

loads and many of the models components can also be

broken down to smaller pieces with the main exceptions being

the hook block, bogies and upper deck plate

The upper deck sits on the bogies and rotates smoothly even

though the model is exceptionally heavy.

The main block is controlled by four winches and these work

really well with a smooth push-release brake.

However it is difficult to raise and lower the hook

using the winches without the tension being lost in some

of the ropes which allows them to jump off the pulleys. The

design of the hook block is such that it does not appear

to be easily broken down into smaller hook blocks so different

rigging options are unavailable. However the hook

block does have working spring-loaded latches which is a

nice touch.

Luffing of the boom is controlled by two winches of the

same design as the hoist winches. However there appears

to be friction in the mechanism as raising and lowering

the boom does not work well using the winches and the

fixed plastic

pulleys under the deck probably do not help with equalising

either. WSI acknowledge this by recommending the luffing

gear is reeved with the boom at the desired angle.

Quality

WSI has produced a very large model with some remarkable

engineering given the forces that apply in something so

big. It is well made. There is some plastic which

is used appropriately and the paint and finish is very

good.

Price

In 2012 this is the largest 1:50 scale crane model available

and there is a great deal of metal for the money, and

some of the pieces are of extraordinary size. On this

basis it is good value for the size offered.

Overall

As a model engineering achievement the Sarens SGC-120 ring

crane sets the bar higher. It is a giant of a model

and will get attention from anyone who sees it. Of

course a collector needs a big wallet and a lot of space

to display it properly. It would look great in an

office, particularly as part of a scene where it is lifting

a heavy element.

It is not the most highly detailed model though. The

real crane is a simple and efficient design and the model

captures that perfectly but at close viewing there are few

graphics or details such as cables and hoses.

Overall it is a great model of the real crane, and a

great model because it just towers over everything and is

certainly outstanding.

Footnotes

The model first appeared at the Nuremberg Toy Fair in 2012

and shipments commenced in June 2012. It was produced

in a run of 500 models.

|

|

|

|

|

| Top layer - Carton

1. |

|

| Bottom layer -

Carton 1. |

|

| Bottom layer -

Carton 2. |

|

| The ring sitting

on the load spreaders. The Cranes Etc team members are

arguing how they left the Haulotte inside the ring. |

|

| Four bogies on

the track. |

|

| With the upper

deck on it towers over Liebherr LTF 1060 mobile crane.

Please don't ask why the Cranes Etc riggers left the crane

in there. |

|

| The Cranes Etc

riggers using powered access. |

|

| Massive steelwork.

|

|

| One of the containers

loaded on a flatbed truck.

|

|

|

|

Hitachi

ZX 210 loading a container with local materials.

|

|

| Yes, it is 'supersize'.

|

|

| The scale of the

crane becomes apparent. |

|

| Spot the

worker.

|

|

| Large winches

and containers.

|

|

| Boom-head eye

view. |

|

| Massive ballast. |

|

| Most cranes

could not even lift the hook. |

|

|