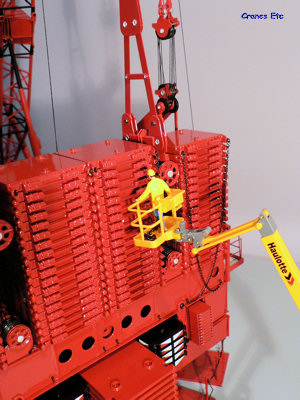

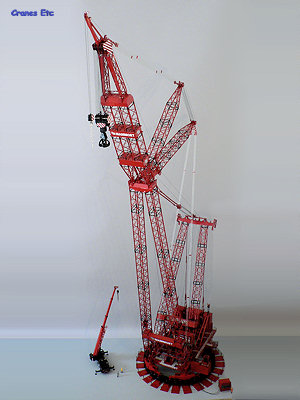

| | On the side of the box it says 'Size Does Matter'. It must do, because this is the biggest model box seen by Cranes Etc. |  |  | | The second tray holds the giant upper structure. |  | | The bottom tray has the ring and all of the counterweight pieces. |  | | Laying out the load spreaders using a Liebherr LTM1070 Mobile Crane. |  | | Do not get your foot caught under one of the pads. |  | | A Haulotte HA20 PX assists in sorting out some cabling. |  | | The operator's cab raised up. |  | | There are plenty of ballast weights to fill up a Goldhofer ballast trailer. |  | | Final assembly using the Liebherr. |  | | The operator's cab tilts, rotates and has opening doors. |  | | This is one big machine. |  | | Warning lights at the top of the runner jib. |  | | Large metal pulleys on the stay beams. |  | | Top of the back mast. |  | | Tremendous detail on the upper structure deck. |  | | A massive structure perfectly rendered in 1:50 scale. |  | | Lifting a massive vessel with ease. |  | | The crane turns smoothly on the massive ring. |  | | The view from the operator's cab. |  | | The load spreaders need to be placed so the access stairs are not fouled when the crane rotates - Step 7 |  | | When raising the main boom strap the back mast and boom together with the elastic bands to make sure the back mast keeps the wires to the 'ballast tree' in tension - Step 30. |  | | Reeving of the runner block line - Step 34. |

| The Mammoet PTC Crane is a very large machine which has been specially built by Mammoet, the worldwide heavy lifting and transportation specialist company headquartered in Holland. The acronym PTC stands for Platform Twinring Containerised. As the user of the crane, Mammoet were able to specify the requirements of the crane more precisely than buying a standard machine from an industry supplier. Photos of the real crane can be seen here.

The key features of the machine are that it can lift up 1600 tonnes at 20m radius with an 80m main boom. It can have a combined boom and jib height of over 170m at the maximum. The small runner line on its own has a lifting capacity of 45 tonnes. The PTC has been designed to be readily transportable so all the parts breakdown into standard shipping container sizes for easy transportation. As a heavy lifting machine it is used particularly in the petrochemical and power industries where large lifting capacities are demanded.

Four PTC cranes have been built and this is a model of PTC III, which is named 'Amalia'.

As the real crane is enormous this scale model is huge too and at the time of the review ranks as the largest mass-produced scale model yet produced.

Packaging

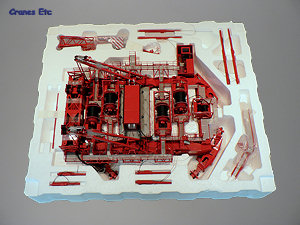

The model comes in a single gigantic box measuring 62cm x 71cm x 50cm (25in x 28in x 20in) which weighs in at around 27kg. As such, it befits the model inside although perhaps the box is a little too large as some collectors will have difficulty finding a place to store a box of this size. Inside the box is a colourful Mammoet sleeve which encloses four large expanded polystyrene trays. Inspection of the trays reveals why the box has such large dimensions. Both the ring and the upper structure pieces are fully assembled and this governs the box dimensions. Within the trays many of the parts are individually wrapped and well protected.

There were no missing parts on the review model. One set of handrails had become dislodged but this was easily repaired with the supplied tube of superglue. It is commendable that a model as large and detailed as this can be shipped across the world with few so ill effects even though it was clear from the external box that it had received some rough handling.

Included with the model is a 28 page manual which has fully detailed assembly instructions in English, Dutch and German. An excellent parts list in the manual details everything down to the number of screws (and thankfully spares are provided). Photos and reeving diagrams are included in the manual although these would have been better printed larger and bolder.

A DVD is also provided and although it is in Dutch, English and German subtitles are available. It includes interesting interviews with Mammoet engineer Patrick van den Berg, and Joep Hansen of WSI. There are also photos of the real PTC. The provision of the DVD is to be commended and in fact it could have gone further if it included the assembly manual (with larger reeving diagrams and photographs) and also the lifting charts and other data about the real PTC.

A Mammoet Certificate of Authenticity signed by the Mammoet CEO Roderick van Seumeren is part of the package, as is a small card with the model serial number. Comprehensive support for the collector continues with the provision of a toolkit which includes scissors, pincers, screwdriver, tweezers, as well as needles, small tube of superglue and a pair of cotton gloves. Two keys bearing the Mammoet name are used to wind some of the winches.

Assembly of the model is straightforward with few problems experienced on the review model. Plenty of time is required with the manual suggesting 10-14 hours and this is about right. To aid anybody building this model some additional assembly guidance is included at the end of this review.

Detail

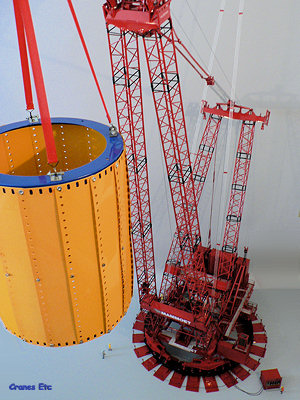

Building the model commences with laying out the load spreaders. These are metal parts and they have posts for a safety chain to be fixed to prevent unauthorised access to the ring. The ring is a large single solid piece which cannot be broken down into smaller parts. It is also metal and includes a jack and base plate for each load spreader. The detail is excellent throughout with cabling within the beam and lifting eyes on the metal pads. A power pack container connects to the ring, and this is fully detailed with control dials and cable drums.

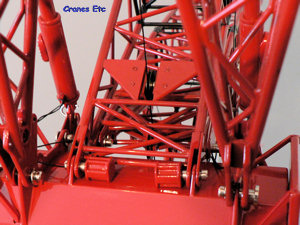

The upper structure is an incredible piece of model engineering. It starts with the rollers that run on the ring. These have an excellent structure with internal access platforms. Internally, cabling can be seen which runs to the drive motors.

Spanning the roller assemblies are four massive box beams which do the main load transfer within the structure. In fact the upper structure has so much detail applied that it tends to disguise the box beams. A maze of walkways crosses the machinery deck. They all have excellent mesh floors and fine scale handrails. The numerous winches are very well detailed with tiny rivets in the cheeks of the drums. Extensive cabling runs to the main power plant. All of the winches are pre-strung with a good quality black thread.

The power plant has entry points for all the cables on the upper structure and this creates a very complex picture of detail which impresses. The four exhaust outlets have working caps on the top.

At the rear of the upper structure various types of ballast weights are used to provide the counterweight. These are detailed and are capable of being posed being lifted by a mobile crane model. The engineering in the ballast area is complex with four banks of pulleys connected to the what the manual calls the 'ballast tree' but is in fact a tray which is suspended from the back mast and can be raised using the pulley blocks.

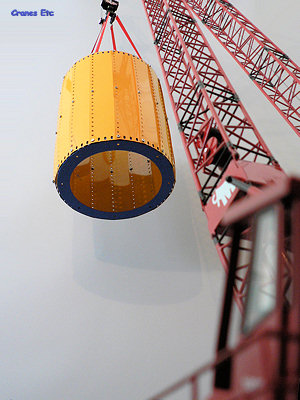

The boom sections are very well made. They consist of small discrete sections which are screwed together and the structure of each is very good with all lattice chord members tubular in section so they are a faithful representation of a real boom structure. The main boom includes pairs of cable drums in each leg which are pre-wired. The pulley sheaves are metal and some of them are first class spoked versions.

Ancillary parts of the boom structure are equally good. The various boom stops are all metal and they have hoses which maintain the high detail level. The main guy ropes are silver coloured to look like steel cables and they have excellent metal spacers. All the main pendant lines are metal and robust enough not to cause any doubt about the strength of the model. At the top of the runner jib some warning lights are detailed and this is a pleasing element.

The main hook block is very heavy, and includes a huge pair of double hooks. Surprisingly the latches on the hooks are non-functioning. The small runner block is also heavy and is a good match for the main block.

Features

The original PTC is designed to be broken down into standard sized container loads for ease of shipping anywhere in the world. Much of the model is pre assembled, but in fact inspection of the boom and the other lattice sections reveals that they are largely made up of small pieces which are screwed together. As such it would be possible to strip most of these parts of the model into fairly realistic transport loads. However this does not extend to the main ring and upper structure and it is easy to see why. These are very complex structures which would be extremely difficult to make separable in this scale without compromising the level of detail or the robustness of the model.

The ring has 24 blocks which can be rotated and lowered on screw threads in order to level the ring. The upper body sits on the ring and rotates smoothly even though the model is exceptionally heavy.

All the other crane functions work well. The main block is controlled by two winches and these both turn smoothly and have very good spring locks. Luffing of the main boom and the luffing boom is by two other similar winches. A smaller winch controls the smaller runner block.

The back mast angle can be adjusted by using the 'Einzieh' which is a balanced pair of winches which are altered by using the supplied keys. It is also possible to lift the 'ballast tree' by using a key. In this way it is possible to replicate increasing the radius of the main ballast for very heavy lifts, although this requires some very careful adjustment of the model.

Among the other features on the upper structure are the operator's cab which is parked within a container, and lifts out on a mechanism. Once out, the cab tilts and rotates. The doors on both sides of the cab also open. Around the sides of the upper structure are various fold down walkways. Also included is the ring power pack in a container. This has an opening flap which reveals the internal controls.

The model can also be set up optionally without the luffing boom and the parts to do this are included with the model.

Quality

Make no mistake about it, this is a very high quality model which matches intricate detailing with massive proportions. The sheer size requires first rate model engineering and this has generally been provided. There is hardly any plastic used on the model at all.

The paintwork is very good and the graphics provided are excellent. Perhaps the only thing that the model is short of is the tiny scale warning notice graphics which are seen on many modern models.

Price

At the time of the review this is the largest mass produced scale model in the world and it has a price to match. Is it worth it? For corporate buyers or museums it is a very affordable way to obtain a very large and detailed model. It will be too expensive for many collectors, but for those that can afford it, it is very good value for the quantity and quality of model offered.

Overall

The Mammoet PTC crane is a remarkable achievement for both Mammoet and WSI. The exceptional size is matched by excellent detail, and thankfully the model engineering is excellent too and it is a revelation to turn the whole model smoothly on the huge ring. There are a few minor issues during assembly, and the reeving activities demand patience as always.

Overall however, this is a benchmark model of what is possible in 1:50 scale. For anyone with the space it is a most impressive crane model. The fine detailing and first class engineering mean that at the time of the review it is one of the best models that has been reviewed by Cranes Etc.

Footnotes

The model first appeared at the Mammoet Open day in September 2007 and shipments commenced in April 2008. The PTC was produced in a run of 1000 models. An Extension Set was introduced in June 2009 which increases the length of the main and luffing booms. A version of the PTC with a double stacked boom was introduced in 2011 in a run of 250 models.

Assembly Guidance

Read in conjunction with the additional photos.

Before commencing assembly of the model, think carefully about where it will be displayed. It is not practical or advisable to lift the model when erected. One solution is to assemble it on a purpose built base with wheels underneath so that it can be carefully slid to another location if required.

The assembly manual that comes with the model is comprehensive, but that is not to say that assembly is an easy task for the novice. These guidance notes can be read in conjunction with the steps listed in the assembly manual to help the process.

Step 2

Box B

The lower stay beam [10] is identified by having two pairs of spoked pulleys at the bottom. The upper stay beam has a single pair.

Box C

The photos for items 17, 18, 21 and 22 do not clearly identify which part is which. The parts are in in fact in order of size with the largest first: 17 (largest), 18, 21, 22 (smallest).

Step 4

Adjust the blocks to level the ring on a hard surface first, rather than doing it on the load spreaders in Step 6.

Step 7

The load spreaders can slide easily if they are placed on a smooth surface, so consider whether to use a roughened surface or something under the load spreaders to prevent sliding. Position the outer edge of the load spreaders at least 40mm (1½ ins) from the edge of the levelling feet. This makes sure the crane can rotate without fouling the posts when the stairs are fitted in Step 35.

Step 10

When fitting the back mast spreader beam fix the counterweight stays (26) at the same time (and not in Step 28).

Step 11

On the review model the long screws do not fit the boom stops. The holes can be reamed out with an appropriate die but if this is not available then in practice the boom stops only need to be pinned and this can be achieved with any appropriately sized and shaped pin (cut from a paperclip for example).

Step 18

If when unfurling the guy ropes it seems that they are made incorrectly and crossed, they almost certainly are not. You will be able to correct any cross-over by examining where the crossover occurs and working out the moves required to untangle the wires.

Step 19, 20

As Step 11, fix the boom stops with any appropriately sized and shaped pin.

Step 22

Ditto Step 18: If when unfurling the guy ropes it seems that they are made incorrectly and crossed, they almost certainly are not. You will be able to correct any cross-over by examining where the crossover occurs and working out the moves required to untangle the wires.

Step 23

This is done more easily when the boom is raised after Step 30. Just make sure that the boom is not raised beyond vertical or it might tip over if the boom stops are not in place! As Step 11, fix the boom stops with any appropriately sized and shaped pin.

Step 28

Another option is to lift the 'ballast tree' up and fix it to the counterweight stays so it hangs, and then use the key to unwind the 'ballast tree' back down to keep the tension on the wires.

Step 30

The stresses in parts of the model are very high if trying to lift the boom from horizontal using winch W1, so lifting the boom manually and winding in winch W1 is recommended until the boom is at least at 45°. However it is very important not to allow the back mast to relax when raising the main boom by hand as this can cause the thread to jump off the ballast tree pulleys. To avoid this, use the elastic bands between the boom and back mast so that the back mast is always held under tension to the boom.

Step 33

An alternative way to reeve the main block is to hang it from the boom head using the four elastic bands (see photo). To assist the reeving cover an amount at the end of the thread with some glue to stiffen it up and make it easier to push through gaps. Do not remove the safety pins in the hook block. Instead, as the thread is passed through the safety pin on each side, fix it in place using a piece of plastic putty to stop it bouncing off later. Before starting the reeving spool out enough thread to be able to complete the reeving (measure from boom top to block, multiply by 15, and add say 0.5m as a contingency). This is how much thread should come over the boom top before starting.

Step 34

The runner block reeving diagram does not explain that the thread goes over the first small black pulley in the lower stay beam [10] and under the small black pulley in the upper stay beam [11].

|

| |

|  | | The top tray has the toolkit, and back mast and boom parts. |  | | The third tray holds the main boom parts and the hooks. |  | | The literature, DVD and toolkit. |  | | The ring sitting on the load spreaders. |  | | Assembly continues. |  | | The machinery deck and power plant. |  | | The operator's cab parked inside the container for shipping. |  | | Assembly continues. |  |  | | Fixing the restraining chains to the ballast weights using the Haulotte. |  | | The ring power pack. |  | | The main hook and runner block. |  | | Very heavy construction of the luffing boom. It is made of smaller screwed together parts so could be broken down into small pieces. |  | | Metal pulleys and heavy attachments to the guy ropes. |  | | The detail is present in inaccessible places. This is underneath the upper body inside the ring. |  | | The PTC dwarfs the Liebherr crane and the Cranes Etc team members. |  | | Very heavy luffing boom. |  | | Excellent steel coloured guy ropes with spacers. |  | | This model will impress anyone. |  |  | | If the long screws do not fit make pins (here out of a paper clip) to hold the boom stops in place - Step 11, 19, 20 and 23. |  | | An alternative way of reeving the main hook - Step 33. |

|