|

| The box. |

|

|

| The push blade

has a reinforced centre and good anti-wear plates at the

bottom. |

|

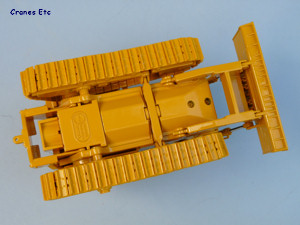

| Underside view.

|

|

| Very good details

on the tracks and drive. |

|

| Heavy connection

of blade and dozer. |

|

| Perhaps a bit

heavy for a

Nooteboom Pendel X Low Loader. |

|

| Pushing a

Caterpillar 657G. |

|

The Caterpillar D10 was announced in

1977 and was the first modern dozer to use a high drive

sprocket. This was designed to produce a more robust

drive mechanism with the resulting additional track wear

not being significant.

In the period 1978-1986 around a thousand units were built

in the USA.

This version is a Push Dozer, and was used to provide additional

effort to scrapers by pushing them during the loading process.

For this purpose the blade mounting was reinforced and the

dozer traction was assisted with counterweight.

Packaging

The packaging is to CCM standards and is very good.

An outer cardboard box contains a presentation box wrapped

in tissue. Inside, the model is contained within polystyrene

trays and has its own tissue wrapping. There were

no defects or missing parts on the review model.

There is no information about the real machine or the

model, and there is no assembly to do.

Detail

The metal track pads are individually linked and detailed.

They are mounted on excellent track frames and the high

drive sprocket is really good with fine bolt details.

The rollers are represented by moving parts.

The engine is plastic but with an excellent colour match,

and there are many components and cables modelled so it

looks realistic. There are excellent metal grab rails

and mesh grilles, with high quality anti-slip surfaces on

various platforms. Lights at the front are represented

by silvered surfaces.

The operator's area is open with a roll over protection

structure (ROPS) and the seat is good with authentic looking

levers and pedals. There is a fire extinguisher on

the outside.

The narrow push blade has a heavy connection to the dozer

frame which also includes small lifting eyes. Detailing

of the blade is good with a thickened central plate where

the blade meets the scraper's pushing point. Viewed

underneath some small cylinders can be seen which

cushion the impact. The cylinders which control the

blades vertical movement have hydraulic pipes and rubber hoses.

At the rear the pushing plates has been modelled well with

bolt head details and a towing hitch.

Features

The tracks roll smoothly and each track set rolls

separately as the drive sprockets are not fixed to the

same axle so realistic turning is possible. The two

track sets are linked transversely so they can move up

and down alternately over rough terrain.

The track tensioners work well with part of the track

frame sliding.

The Push Blade raises and lowers, but cannot easily be removed

in order to pose the model in a transport configuration.

The blade holds any pose set.

Quality

The model has a high quality feel and there is little plastic.

The paint finish is very good and the graphics are sharp.

Price

The model is good value for the quality provided.

Overall

This is another very good example of the D10 by CCM, and

would pose well with suitable scraper models. The

very good quality and detail easily earns it a highly recommended

badge.

Footnotes

This model was introduced in 2010 in a run of 1000 models.

A version was also made in a

U blade configuration

with ripper.

|

|

|

|

|

| Profile view.

|

|

| This is a big dozer. |

|

| Push plate at

the rear.

|

|

| Excellent

engine detail. |

|

| Rabbits-eye

view. |

|

| Discussing

whether it is too heavy. |

|

| Sometimes you

have to push your weight around. |

|