|

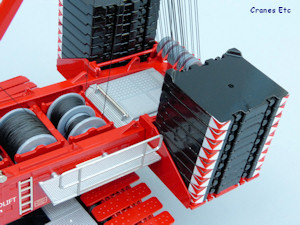

| The large Liebherr

box. |

|

|

| The middle tray

contains the crane body, lattice sections and hooks. |

|

| The model makes

very good transport loads. The body of the crane is fixed

with transport

adaptors.

|

|

| The crane

offloaded and standing on jacks. |

|

| Self assembling

the crawler tracks. |

|

| The 300t hook

fitted. |

|

| Tracks are wide.

|

|

| Tilting cab. |

|

| Large main boom

and derrick fitted. |

|

| Rigged with the

suspended ballast tray. |

|

| Tonnes of

ballast for a big lift.

|

|

| Wagenborg

colour scheme is attractive.

|

|

| Big model. |

|

Comment on this model. Comment on this model.

This is a model of the giant

Liebherr 1750 Crawler Crane which has a lifting capacity

of 750 tonnes. It has a maximum height of lift of 191m

and can be configured in a variety of ways including

adding special boom sections for wind turbine work.

It is also a sister machine to the

Liebherr LG 1750 Truck Mounted

Crane as many of the crane components are shared.

The version reviewed here is in the colours of

Wagenborg Nedlift, the Netherlands heavy lifting and

transport specialist. It is configured with a suspended

ballast frame arrangement.

Packaging

The model box is very large and extremely heavy, and

care is advised in handling it. It consists of a

picture sleeve which wraps the three expanded

polystyrene trays which contain the model, complete with

a lid for the top tray. There were no defects or

missing parts on the review model.

A 26 page manual is included which is printed in black

and white, and two additional sheets cover the suspended

ballast tray in this

version of the model. It has photos of the box trays

with parts annotated so they can be identified during

the assembly process, although and not

every piece is actually identified.

The assembly instructions

themselves are a series of staged photographs with the components

at each stage identified. Although the pictorial stages are fine,

the instructions fall short in the area of reeving the model.

There is a lack of a clear description of which winch drums

should control which function and where for example the

hoist ropes should run through the derrick. There

are reeving diagrams for the three sets of luffing gear

which are barely clear enough in black and white, but nothing

at all for reeving the hooks. It is a little disappointing

that the model falls a bit short in this area.

With that said, the assembly of the model is enjoyable

because Conrad's model engineering is top notch and the model

parts fit together very well indeed. As usual the reeving can try the

patience and this model is no exception. Stringing

up the hooks can lead to frustration as the string has a

tendency to bounce off the pulleys so the best bet is to

keep the string under tension at all times.

Full assembly of the complete configuration takes

several hours.

Detail

Each track frame is a large single piece consisting of

the main structural frame which has some interesting

casting detail. The drive sprockets are detailed and

bear the Liebherr name finely cast in. The track pads

are wide representing the 2m track pad option of the

real crane.

The centre section is a heavy piece and has the crane

body permanently attached. There are four outriggers

with jacks for lifting the crane body off a transport

vehicle. The outrigger pads are plastic but they are

not visible when the model is fully assembled. Also

spanning the track frames is a pair of brackets which fit onto

clips which attach onto the frames, and these support

three ballast plates each. These are the usual high

standard of casting including lifting lugs. On top

of the plates, silver textured walkways rest to provide

a platform for operator access and this part of the model

is completed by a couple of ladders and handrails.

A heavy toothed slewing ring sits on top of the undercarriage.

The crane body has a swinging cab which includes a walkway

and handrails but does not have some of the smaller details

such as wipers and mirrors. Inside, the cab has a

representation of controls and screens. The crane

body is heavy and has essential detail within the casting

representing panels and handles, and there are a couple

of ladders. At the front, the three slewing motors

look realistic, and they are complete with drive pinions,

although there are no hydraulic lines modelled.

There is a small auxiliary winch at the front and this

looks best when it has some thread wound on.

The Wagenborg livery is very attractive and includes

good graphics on the sides of the body including a fleet

number.

Moving

to the rear, the engine enclosure includes textured surfaces

and grilles and a metal exhaust pipe. The grille detail

also extends to the underside of the body. Heavy ballast

trays hang off each side at the rear. The A-frame includes

the hydraulic hook which the crane uses to assemble its

own tracks.

The suspended ballast frame pins to the back of the

crane and has a textured walking surface and nicely

rendered metal handrails. Ladders descend to the

support bed, and the support mechanism is detailed

within the casting, but the cylinders are non

functioning. The ballast plates are very good,

with lifting eyes that facilitate lifting with suitable

chains to make an interesting pose.

The boom and jib sections are all fine examples of

Conrad’s model engineering ability. Geometrically

perfect, they fit together extremely well. They are

joined together by the usual Conrad plastic pins which

work fine. At the crane body, spring loaded back stops

prevent the booms from over luffing and these parts are

all metal. All of the pulleys are plastic, and are free

rolling. The suspension bars are plastic and pin together

maintaining a true line when under load so they are much

better than those supplied with the early versions of

the model.

The luffing bridles are plastic, presumably to keep the

weight of these parts down so that the lines do not sag

unduly. Another plastic part is the pulley holder on

the main boom head and this would certainly have been

better in metal like the luffing jib head, which is a heavy piece. Plastic

Liebherr signboards are fixed to the boom and jib.

Two hooks are provided and these are impressive. Consisting

of the same modular components, they strip down to separate

pulley block and hook assemblies with only the pulleys and

pins being plastic. The larger hook also has clip

on ballast weights to keep the tension in the ropes.

Features

The model features working jacks to lift the crane body

off of a transport vehicle. These rotate out from

the cross frame and screw down to lift the crane.

The crawler tracks roll nicely and are mounted on a

frame which is spring loaded at one end which keeps the

tension and also enables removal of the tracks.

The cab is a swinging type which tucks in at the front

when in transport mode. It can also be tilted to allow

the operator comfort when the crane is lifting at

height.

A working hydraulic hook is provided which is connected

to the A-frame so that the crane can assemble its own

tracks. This has a suitably stiff cylinder so that

the hook can be posed at a variety of lengths and hold a

load without the ram ‘bleeding’.

All three hoist drums in the crane body are spring

loaded and resistant to slipping under load. They are

operated using keys which push through holes in the

crane body and they have a slotted end so they can be

driven using a powered screwdriver. The three hoist

drums mounted in the boom and derrick

sections are operated similarly so that all the

functions of the real crane can be replicated.

The boom drums are also pinned in position so are

removable.

The suspended ballast frame is attached to the

crane with a telescopic mechanism which allows it to be

set at three different extension radii depending on the

lift to be undertaken.

The large 600t hook is modular and can be broken down to

form a separate 300t hook.

A major strength of the model is the ability to build it

in a number of configurations. Booms and jibs can be

any length desired. A luffing jib can be mounted, or

not, and the derrick is also an optional fixture. Similarly

a variety of ballast weight configurations is available.

The modular construction also allows it to be used to

make up a large number of transport loads.

Quality

The quality of manufacture is very good indeed with the

metal lattice sections straight and true, and it fits

together really well.

The paintwork and graphics are very good and plastic is kept to

a minimum.

Price

This is a limited edition and is a significant amount of

metal so it is not cheap. It is good value for

what is offered.

Overall

Conrad has produced a very large model which fully

erected is an imposing 2m high and although the stresses

get significant with a model of this size there is never the feeling that

it cannot take the loads applied.

The display possibilities are excellent because of the

different configurations possible, and it can be broken

down into transport size loads.

Although the manual could be a little better there is no

doubt that in Wagenborg livery this is an outstanding model.

Footnotes

The model first appeared at the Nuremberg Toy Fair

in February 2005 in

Liebherr colours. In 2007 the sister crane, the truck mounted

LG1750, was announced by Conrad as

model 2737.

This Wagenborg version appeared in September 2012.

|

|

|

|

|

| The top tray holds

the tracks, suspended ballast tray and lattice sections. |

|

| The bottom tray

has the ballast plates and various sections.

|

|

| A heavy crawler

track on the road. |

|

| Crane parts are

large. |

|

| Large 600t hook

is modular. |

|

|

Rigged with a short main boom only. |

|

| The main boom

head. The pulley arrangement is pinned and can be

left off if the luffing jib is fitted.

|

|

| Textured engine

cover. The winch drums and pulleys are plastic. |

|

| Ballast on

the undercarriage. Putting some rope on the

auxiliary winch looks better. |

|

| Heavy crawler

track frames. |

|

| Big iron. |

|

| Luffing jib. |

|

| Very realistic

appearance. |

|

| Lifting a

fermentation tank with ease. |

|

| Impressive

model engineering. |

|