| | The large box. |  |  | | The bottom tray is packed full. |  | | The Ringer under assembly, assisted by a Grove GMK 3055. |  | | The boom pivot point sits on the ring. |  | | The ring structure with stiffeners to prevent buckling of the ring under load. |  | | Ring structure and cab. |  | | The top of the back mast. |  | | The heavy construction makes an impressive model. |  | | The Ringer is shown rigged with an extra set of 40ft boom straps (which are not included with the model). Some collectors may prefer this look, and it additionally allows the boom to be lowered to a much lower angle. |

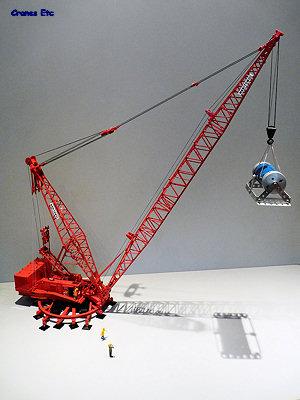

| This is the third version of the Manitowoc 4100W model produced by TWH to celebrate this historic crane from the Manitowoc Crane Company. This version is a heavy lift crane, which is mounted on a load bearing ring that allows the capacity of the basic crane to be increased significantly so that it can lift 100 tons at almost 100ft radius.

Packaging

The model comes in a large stylised box with a photo showing the configuration of the model although it is not quite the same as the model in the box as it shows additional 40ft pendants (straps) which are in fact not included. Within the box are two fairly crowded expanded polystyrene trays, which contain the pieces of the model, all well wrapped in polythene. The review model had no defects or missing parts.

A twelve page instruction booklet is provided with the model and it is very good, including an inventory of parts and showing clear assembly steps. A Manitowoc branded screwdriver (complete with the appropriate aged logo) is supplied to assist the assembly. The back mast reeving is already done in the factory although the thread is tied with masking tape to keep it together and this can be fiddly to remove. It is recommended that before the model is assembled that some plastic putty or similar material is pressed on to the pulleys to stop the thread bouncing off whilst undoing the tape. A couple of hours should be allowed to fully assemble and rig the model. The main hook has to be reeved but this is one of the easiest large crane hooks to reeve so should present no problems. An additional small leaflet shows how the access ladder should be fitted.

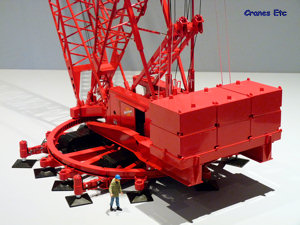

The ring and tracks are one piece out of the box and it does not appear to be designed to be easily taken apart to make transport loads. The main support structure is screwed onto the track frames although the screws are not easy to reach. Each levelling jack beam is screwed to the ring so these can be undone although some of the beams are connected into the structure between the track frames and would be more difficult to remove. The ring itself is made up of four segments but these appear to be riveted together. Most collectors will not want to attempt any disassembly.

A reproduction of an original marketing brochure is also included which is a nice touch.

Detail

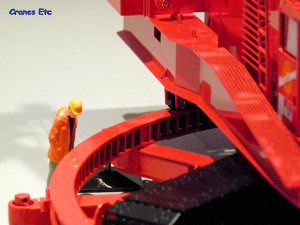

The metal linked tracks are excellent and the track frames have the same high detail as the earlier versions of the 4100W. The spoked drive sprockets look good and the realistic working chain drives are modelled. The ring is made up of sections which replicate the structure very well, with stiffeners to prevent buckling on the inside of the ring beam. The main structure and struts are excellent and convincing castings, and include lifting eyes on the largest parts. The pads are metal and there is some excellent hosing to the main adjustable jacks, with a hydraulic pump and control box on one side of the ring.

At the side and rear of the crane, a heavy structure supports the additional rear counterweight which rests on the ring. It has a textured walkway surface alongside the body. At the back six large counterweight boxes stack neatly. They are fairly heavy without feeling solidly full. Unfortunately they lack properly formed lifting eyes so it is not possible to pose the boxes being lifted into position during erection. At the front, the boom pivot point is another heavy piece and includes a nice A frame with pulley guides for the hoist ropes.

The crane body impresses because of the fine paintwork and graphics. The cab is fully detailed inside with seat and control levers, and the details continue outside with patterned walkways, windscreen wiper and grab handles. The cab door has some exceptionally fine graphics applied. Behind the cab is a metal ladder leading to the roof and behind that is a fine slatted grille. At the rear, the standard counterweight blocks are smoothly finished. Opposite the driverís cab side is another sliding door and this reveals the engine compartment complete with various pipe work.

The roof of the crane body has an exhaust with chrome muffler, and the gantry structure is very well detailed with step irons leading to a ladder which provides access to the top of the gantry. All pulleys are metal and the model engineering in this area is high quality. The equaliser which controls the back mast is reeved in the factory, but it is also a fixed length of thread and so cannot be controlled by a winch. With that said, a great job has been done ensuring that all the straps for the back mast are taut with nothing left flapping forlornly.

Turning to the booms, the back mast is made up of pieces very similar to the boom top and boom butt of the base crane model. Two metal cylinders form part of the structure which fixes the back mast in position. The main boom is made up of larger #27 boom sections and these are every bit as good quality as the #22 sections, with the main chord members cast to replicate the inverted angled sections of the original. The 40ft boom section also includes a pair of functioning rollers for the hoist ropes on the boom top which is a nice detail. The main boom sections have internal bracing. The screwed connections between sections are good and positive and the pulleys in the boom top are metal and free rolling.

Two hooks are provided with the model. The larger one is a six sheave block which is heavy enough to lower when the winch is unwound and it includes a latch on the hook. The boom head also includes six sheaves which means that when fully reeved there is a spare pulley in the block and it tends to sit not quite plumb.

A single line headache ball is also included and this provides an alternative rigging option.

Features

The tracks roll freely without interference from the ring supporting structures. All the pads on the ring can be individually raised and lowered to level the model and it is possible to raise the pads to allow the crane to rest on the tracks.

The standard counterweight is supplied as a number of pieces which push-fit together and fit to the crane body, and the ring counterweight blocks can be stacked as desired.

In addition to the two sliding doors and opening chain case there is an opening hatch on the roof which allows a view into the engine compartment.

The crane functions all work well. Rotation of the crane on the ring is very smooth. The luffing and winch drums are operated using keys which insert through holes in the bodywork and these work fine, not slipping under load. The main hook block has a working safety latch and the hook fully swivels which allows a load to be suspended at any orientation.

There are some constraints to the setting up of the model which reduce the number of possibilities for posing it. The ring is essentially fixed, and although the components which sit on the ring are removable, they are not sized in a way that they can make realistic transport loads for a suitable truck. The back mast position is fixed also and so it is not possible to show the back mast in an assembly position lying horizontal on the ground without carrying out some alterations to the model. The main boom can be luffed, however the thread on the drums is limited so it is not possible to lower the main boom to a horizontal position which will disappoint some collectors. If the thread is fully unspooled you can see that it is in fact knotted onto two short lengths leading to the drum so it may be possible to add more thread by splicing some in, although knots will then be visible on the model. The alternative is to replace the whole thread with a much longer length but it is hard to see inside the model to determine whether the drums would become overfull leading to operating problems.

The model is very stable on the ring, so it can be posed with a reasonable load hung from the hook.

Quality

This model maintains the high quality standard set by the other versions of the 4100W. The castings, paintwork, graphics and detail are all very good.

Price

This model is very good value overall.

Overall

This ringer version of the 4100W fully achieves the objective of being a high quality model of a famous crane. There is no doubt it looks impressive and makes a great display piece. Some of the functionality of the model has been constrained by certain modelling compromises that have been made, and some collectors would certainly have preferred the model to have had more flexibility in its display possibilities. Overall this is another first class model that will satisfy collectors and would additionally make a very good display for museum or corporate uses.

Footnotes

The model first appeared in November 2008. The run of the model is 2500. It is marketed outside the Americas by NZG as model number 693. Other variants of the 4100W model: crane, dragline and tower crane. An Extension Kit for the ringer crane includes extra back mast and boom sections, and a #123 fly jib. In June 2010 a run of 125 models in Lampson blue was announced. The extension kit was also produced in Lampson blue.

|

| |

|  | | The ring in the top tray. |  | | The many parts out of the box. |  | | One of the four main jacks. It looks like a proper cylinder and not a screw thread. |  | | Opening door reveals the engine. |  | | The large hook block. The safety latch opens. |  | | The main boom with #27 boom parts. |  | | The counterweight blocks. |  | | Top view with the equaliser demonstrating realistic 'sag'. |  | | Lifting a heavy beam at radius. This is just about the maximum radius due to the limited amount of thread on the luffing drums. |  | | The model is rock steady and stable. |

|