| | The box is in the typical 4100W style. |  |  | | The parts out of the box. |  | | Typical lines of the 4100W. |  | | The gantry at the rear is fixed down when operating in the tower crane version. |  | | The counterweight attached. |  | | Sliding door gives access to the engine. Here an Elliot Fuel and Lube Truck gives some service. |  | | The tower is impressive. |  | | The boom shown in a horizontal pose. The model is perfectly stable like this. |  | | Lowering the boom to an 'out of service' position. The pivot point of the boom moves as the boom is lowered. |  | | With the boom fully lowered, the gantry can be raised. |  | | The backstay is disconnected. The Cranes Etc team stand well clear. |

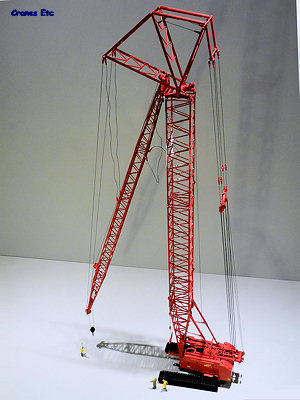

| This is the fourth version of the Manitowoc 4100W model and it is the biggest. It is produced by TWH to further celebrate this historic crane from the Manitowoc Crane Company. This version is a tower crane, which has a vertical tower and a smaller dimensioned boom which allows the crane to lift up and over and is therefore particularly suited for use on building construction.

The crane could lift up to 30 US tons however its real strength was lifting at height and radius. The tower could be up to 183ft (approx 60m) high in self erect mode, and up to 253ft if assisted by another crane. The boom could be up to 170ft long.

Packaging

The model comes in a large stylised box with a photo of the crane on the lid. Within the box are two expanded polystyrene trays, and the bottom one is packed full whilst the top one acts as a lid put also has a mast section inside. The model is very well wrapped in polythene and it had no defects or missing parts.

A very good detailed instruction booklet is provided with the model, and it includes an inventory of parts and shows clear assembly steps. A Manitowoc branded screwdriver (complete with the appropriate old logo) is supplied to assist the assembly. The back mast reeving to the equaliser is already done in the factory although the thread is tied with masking tape to keep it together and to help prevent thread jumping off the pulleys. To make things easier for collectors, the mast luffing ropes are reeved in the factory. A couple of hours should be set aside to fully assemble and rig the model.

The instructions are very good but there are a couple of issues. As a minor point the parts list shows the pendants (straps) being separate parts. In fact they are already attached to the various parts of the model which actually makes things easier. A more important point is that step 3 of the instructions shows a 40ft mast section fixed to the mast butt. In fact with the actual model in the box you need to attach the 10ft mast section at the bottom of the mast because this has the boom latch fixed to it, and this needs to be at the bottom of the mast. On the real crane the boom latch is actually fixed to a 40ft section as envisaged by the assembly instructions.

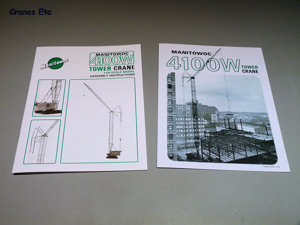

A reproduction of an original 1976 marketing brochure is also included which adds to the collectability of the model.

Detail

The metal linked tracks are excellent and the track frames are very detailed. Particularly fine points are the spoked drive sprockets and the realistic working chain drives which move as the tracks are used. This version of the crane does not include ballast boxes between the track frames.

The crane body impresses because of the fine paintwork and graphics. The cab is fully detailed inside with seat and control levers, and the details continue outside with patterned walkways, windscreen wiper and grab handles. The cab door has some exceptionally fine graphics applied. Behind the cab is a metal ladder leading to the roof and behind that is a fine slatted grille. At the rear, the counterweight blocks are smoothly finished. This version of the model includes the two cheek weights which are an aid to stability, but they were not used on the real version of the crane. Opposite the driverís cab side is another sliding door and this reveals the engine compartment complete with various pipe work. At the front, the hold back assembly is very nicely done and it is great that the connections on the ropes are screwed not riveted so that they are easily disconnected if desired.

The roof of the crane body has an exhaust with chrome muffler, and the gantry structure is very well detailed with step irons leading to a ladder which provides access to the gantry top. All pulleys are metal and the model engineering in this area is high quality.

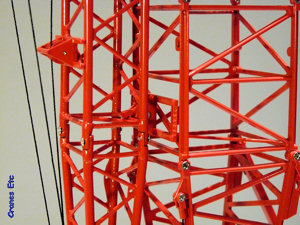

The mast is made of the same high quality #22A sections as the rest of the range of 4100W models and is complete with internal bracing. The short 10ft boom section has the tower boom latch attached. This is used to clip the boom to the tower when raising or lowering the whole assembly, and it is well made on the model. At the top of the mast is the tower cap. This is a complicated but well made piece with very well rendered structural detail and metal pulleys. It also includes the first length of boom section which is another example of excellent lattice work. The only downside of the tower cap piece is that the connections are all riveted meaning that it is not possible to strip it down further without surgery on the model.

A couple of boom stop pendants are fixed at the front and these are to prevent the boom being luffed to too step an angle and then potentially falling backwards. However on the model they seem to be scaled too long. The rest of the boom is excellent. Even though it is of a small cross section compared to the #22A sections it has internal bracing at the end of each section. The boom tip has metal spoked pulleys and small metal Manitowoc sign boards.

A single hook block is provided with the model and this has a single pulley. It is simple and effective. It would have been nice if the model had included a single line hook as an alternative rigging option, and a set of lifting chains.

Features

A clear feature of the model is that is big, standing 80cm (32in) to the top of the mast, with another 70cm (28in) of boom length. It is impressive as a result.

The tracks roll freely and the track frames are screwed and detachable from the main undercarriage so they can be refixed at a slightly narrower transport configuration, although this was not tried on the review model.

The counterweight is supplied as a number of pieces which push-fit together and fit to the crane body so it is possible to replicate a reasonable transport pose by removing them.

In addition to the two sliding doors and opening chain case at the front there is an opening hatch on the side to provide access to the battery compartment. The hatch on the roof also opens to allow a view into the engine compartment although this is not useable when the gantry is down in the working configuration on this version of the model.

The model functions all work well including rotation of the crane. The luffing and winch drums are operated using keys which insert through holes in the bodywork and these work fine, not slipping under load.

The model is designed to be displayed in its fully erected state but it can be shown in other ways too. The boom can be fully lowered and the mechanism on the tower cap to offset the boom pivot works very well. On the review model there was a slight scaling or manufacturing issue where the lower strut engages as the boom is lowered as it does not interlock in the forks properly, but this is more cosmetic and does not affect the functionality. The boom can be fully lowered in an out of service condition and can be attached to the mast using the boom latch.

It is also possible to simulate the lowering of the mast, partially at least. To achieve this the rear counterweights have to be removed and the screws holding the gantry in the folded position removed. Care is required because the gantry will jump up if the equaliser is under tension. The counterweight should be replaced and the pins holding the backstay gantry removed. It is then possible to commence lowering the mast with the boom clipped on via the latch. On the review model the mast could not be fully lowered due to a shortage of thread on the luffing drums and in any event the model is only stable up to about the same point. Advanced collectors may want to replace the luffing thread with a thinner gauge thread at a length that permits the mast to be lowered fully.

Most of the parts of the model would make excellent transport loads and only the riveted nature of the construction on the tower cap prevents this section looking good on a truck too.

Quality

This is another high quality version of the Manitowoc 4100W and continues the excellent standard of detail and finish of the earlier models in the series. Paintwork and graphics are excellent.

Price

As with other models in the series this version of the 4100W is very good value overall, particularly for the size of model provided.

Overall

In some ways this is the most impressive model of the series because of its large size out of the box. The quality and overall presentation of the model is very good indeed. The functionality of the model is also very good, and with a few minor amendments it would have been top notch. There is no doubt this is another first class model which will be appreciated by collectors and corporate customers alike.

Footnotes

The model first appeared in December 2008. The run of the model is 1500. It is marketed outside the Americas by NZG as model number 694. Other variants of the 4100W model: crane, dragline and ringer. An Extension Kit for the tower crane includes extra mast and boom sections.

|

| |

|  | | The tray is packed. |  | | Two brochures. |  | | Excellent cab details and warning notices. |  | | Opening door at the front. Excellent track drive chains. |  | | The small flap opens to give access to the batteries. |  | | The hold back assembly at the front. |  | | The tower cap is mechanically complex. The boom stop pendants are made of thread so they do not hang 'naturally' under their own weight. |  | | The boom tip and hook. |  | | The boom latch is visible in the centre of the photo. This clips the boom to the mast and is why the boom latch really needs to be at the bottom of the mast. |  | | Lowering the mast. This is as far as it would go on the review model before the luffing rope ran out. It is also just at the tipping point when the crane wants to fall over. |

|